Understanding and Comparing Two-Wire and Three-Wire Submersible Well Pump Motors

Understanding the Differences Between Two and Three Wire Motors

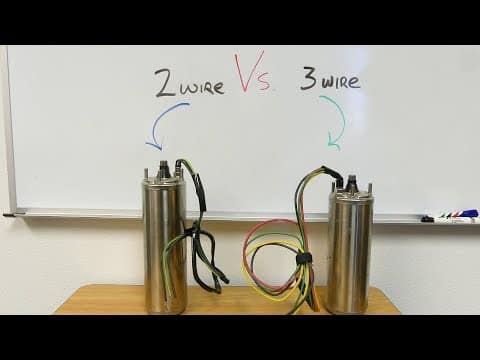

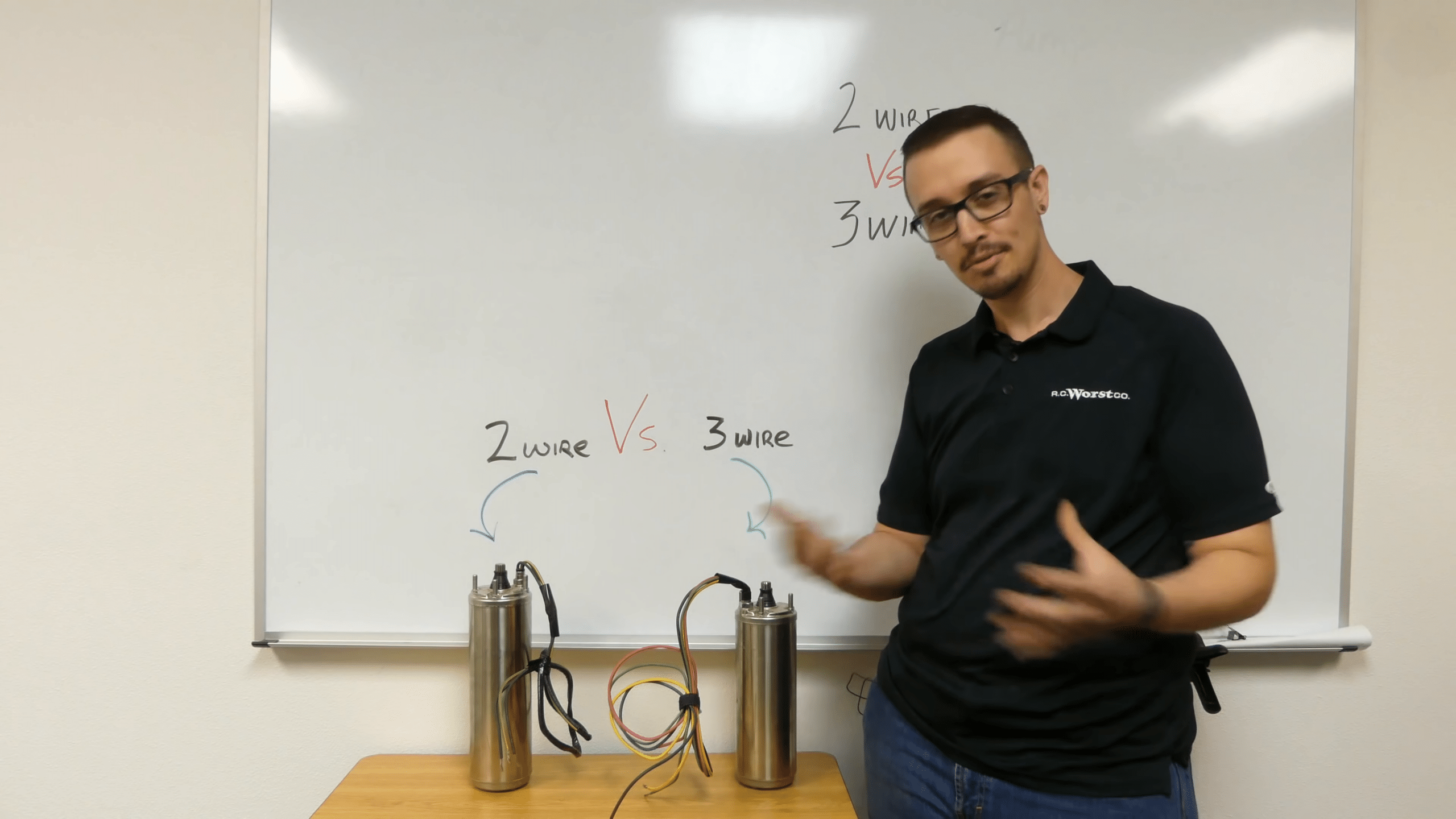

In the realm of submersible well pump motors, understanding the distinctions between two-wire and three-wire configurations is crucial for selection based on application requirements. Two-wire motors typically consist of two black wires and a green ground wire, which is crucial for safety but not counted in the wire count. These motors are notably simpler to connect as they generally do not have a polarity issue. On the other hand, three-wire motors, which consist of a red, a yellow, and a black wire, require more attention during installation as each wire must be correctly connected to its corresponding terminal in a control box, which is well-labeled to aid this process.

The distinction in wiring also extends to the motor’s operation and the setup of its starting mechanism. Two-wire systems are generally more straightforward and less expensive, but they are limited to motors with a maximum of 1.5 horsepower. In contrast, three-wire systems can handle motors up to 15 horsepower, providing a scalable solution for more significant, more demanding setups without needing to transition to three-phase systems.

Exploring Motor Types: PSC, Split Phase, and Induction

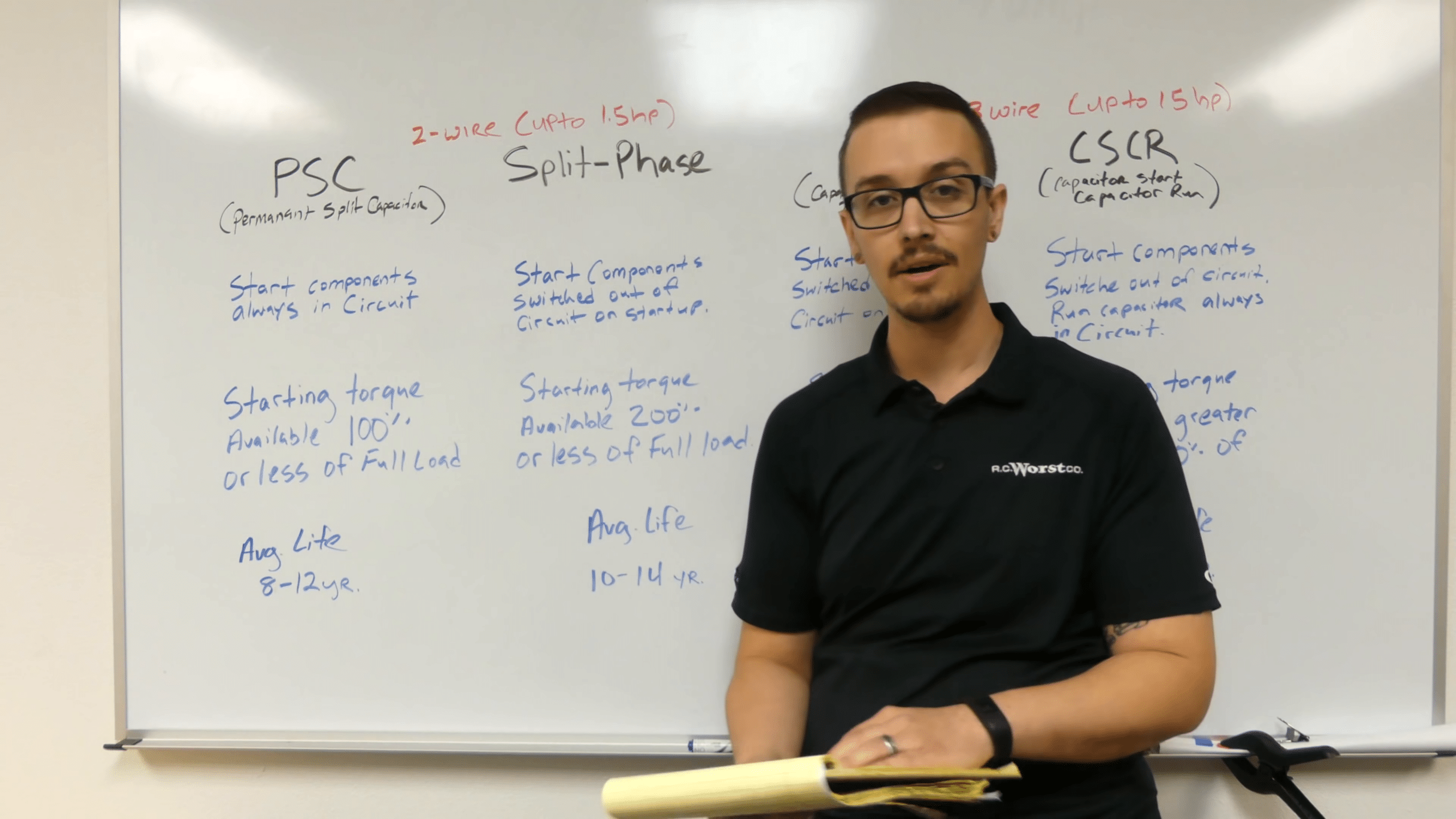

Three primary motor types are common in submersible well applications: Permanent Split Capacitor (PSC), Split Phase, and Capacitor Start Induction Run (CSIR). Each type has its specific characteristics and applications. PSC motors, for instance, have their start components always engaged, which boosts reliability but can slightly diminish operational efficiency and longevity. This continuous engagement means that the start capacitor, which gives the initial surge to start the motor, is always in the circuit.

Conversely, Split Phase motors, which currently may only be offered by Franklin Electric, include a specialized switch mechanism. This switch can disengage the start components after the motor starts, reducing electrical consumption and wear. An added functionality of the switch in Split Phase motors is its ability to ratchet the motor shaft to clear any blockages such as sand, enhancing motor resilience and reliability.

Comparative Analysis of Starting Torques and Lifespan

Starting torque is a critical factor, especially in environments where motors face high initial resistance. Two-wire PSC motors typically provide a starting torque of 100% or less of full load, while Split Phase motors offer up to 200%, enabling them to handle tougher starting conditions more effectively. The robust starting torque is beneficial in scenarios where pumps might become clogged or face high-viscosity fluids right at the start.

As for durability, PSC motors have a respectable lifespan, generally ranging from 8 to 12 years, depending on usage and environmental conditions. Split Phase motors can extend a bit further, offering around 10 to 14 years due to their enhanced mechanical design and reduced wear during operation. This makes them slightly more suited for long-term applications where reliability is paramount.

Advanced Three Wire Motor Features and Configurations

Delving deeper into three-wire systems, the CSIR setup involves a scenario where the starting components disengage once the motor reaches approximately 70-75% of its operational speed. This setup generally provides a starting torque of about 350% of full load, significantly enhancing the motor’s ability to overcome initial inertia. The CSCR (Capacitor Start Capacitor Run) configuration maintains a run capacitor continually engaged during operation, which helps stabilize load transitions and improve efficiency.

While CSIR is more common, CSCR panels are often preferred in applications involving prolonged motor runs, such as in irrigation systems or fountains, due to their increased efficiency and slightly prolonged lifespan. The choice between CSIR and CSCR often comes down to specific application requirements and geographic preferences, with CSCR panels reportedly being more popular on the East Coast of the United States.

Cost Considerations and Long-Term Investment

When considering the financial aspect, the initial price point and ongoing operational costs are crucial. Interestingly, a comparison of a 1.5 horsepower two-wire motor and a three-wire setup (including a control box) reveals that the three-wire configuration may offer marginally lower initial costs and potentially lower long-term operational costs due to its higher efficiency and durability. Additionally, the three-wire system’s control box is usually installed above ground, making it more accessible for maintenance or replacement of components, which can significantly reduce the cost and complexity of repairs.

Overall, while two-wire motors offer simplicity and cost-effectiveness for lower power applications, three-wire motors provide greater flexibility, efficiency, and longevity, making them a preferable option for those looking to maximize their investment in a submersible pump system. Whether for residential water supply, agricultural irrigation, or commercial applications, choosing the right motor setup is critical for optimizing performance and minimizing downtime and maintenance costs.