Optimizing Drain Line Configurations for a Three-Fixture Bathroom: A Guide to Plumbing Layouts

Understanding the Drain Line Layout for a Three Fixture Bathroom

When planning the plumbing for a bathroom incorporating a toilet, lavatory, and shower, understanding the proper drain line layout is crucial for functionality and compliance with building codes. The setup often involves a wet venting system, which can be a bit complex for those unfamiliar with plumbing principles. Starting with the toilet, it’s important to ensure that the toilet flange is positioned correctly. The center of the flange should be 12 inches from the finished wall and at least 15 inches from any side obstructions to meet standard code requirements.

The line leading to the toilet should be a minimum of three inches in diameter. If the vertical distance from the top of the flange to the horizontal branch line exceeds 12 inches, a long sweep fitting is necessary instead of a standard 90-degree elbow. This setup helps in maintaining a smooth flow of waste. Additionally, the slope or pitch of the pipe should be at least an eighth of an inch per foot to ensure proper drainage, though slightly increasing this pitch can be beneficial for better flow.

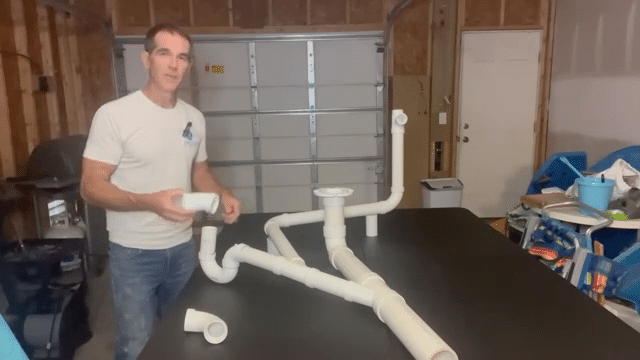

Integrating Lavatory and Shower Drains

Further along the system, a three by two-inch wye fitting is used where the lavatory and shower drain lines connect. This configuration allows these fixtures to share a wet vent, simplifying the venting requirements and saving space in the plumbing system. It’s essential to use a two-inch pipe for this connection because it acts as a wet vent, although larger sizes could enhance the system’s performance. In terms of grading, a minimum of a quarter inch per foot is standard for two-inch pipes, which helps in effective waste removal.

One must also consider the number of turns in the drain lines. In certain jurisdictions, such as North Carolina, the code allows up to four horizontal turns (equivalent to 45-degree bends) before requiring a cleanout installation. This rule ensures that there are accessible points for addressing blockages without needing to dismantle the entire system. Careful planning of these turns is crucial to maintain compliance and functionality.

Proper Placement of Traps and Vents

The placement of a P-trap and its associated trap arm—the section of pipe between the trap and its vent—is vital. For example, in a two-inch trap arm setup, the maximum allowable length is eight feet. This limitation ensures the fixture can properly vent, preventing issues like slow drainage or siphoning of water from the trap. Venting plays a critical role in maintaining the water seal in the trap, which blocks sewer gases from entering the home.

The dry vent for the lavatory begins where it ties into the main stack or vent system. This vent should typically be half the diameter of the drain it serves. For instance, if servicing a three-inch toilet drain, the vent line should be at least an inch and a half in diameter. Proper vent sizing is crucial to allow adequate airflow to balance the pressure within the drain system, preventing water seals in the traps from being blown out or siphoned off.

Controversial Practices in Plumbing Venting

A particularly controversial topic in plumbing is the use of air admittance valves (AAVs). These devices allow air to enter the plumbing system to equalize pressure when waste water is flowing through the drains. However, they do not permit sewer gases to escape into the home, which can be a critical failure point. Opinions vary widely among professionals—some appreciate the convenience and cost-effectiveness of AAVs, especially in complex venting scenarios or where traditional venting is impractical. Others criticize them for potential reliability issues and non-compliance with some local building codes.

Determining the appropriateness of AAVs often depends on specific local regulations and the unique conditions of the plumbing system being installed. They can be a useful solution in certain contexts but may not be suitable or legal in others. As with many aspects of building trades, continuing education and staying informed about code updates and new technologies are key for professionals in the field.

Understanding and implementing the correct plumbing layout in residential bathrooms requires knowledge of both the physical constraints of the space and the legal requirements set forth by building codes. By adhering to these guidelines and considering options like AAVs carefully, professionals can ensure efficient, compliant, and functional bathroom plumbing systems.