Key Plumbing Code Violations and How to Avoid Them

Common Plumbing Violations to Avoid

When it comes to plumbing, adhering to code requirements is not just about passing inspections—it’s crucial for ensuring safety, functionality, and maintaining the integrity of your property. Unfortunately, whether it’s a DIY project or work performed by a contractor, certain common mistakes can lead to failed inspections. Understanding these common pitfalls can help homeowners and professionals alike ensure their plumbing systems are up to standard.

Washing Machine Drain Specifications

A frequent oversight in residential plumbing is using the incorrect pipe size for washing machine drains. The current plumbing code mandates that the washing machine’s P-trap and the pipes connected to it must be at least two inches in diameter, rather than the older standard of an inch and a half. Additionally, the standpipe should be positioned 18 to 30 inches in height and must be 6 to 18 inches off the floor. Non-compliance with these specifications will result in an immediate inspection failure.

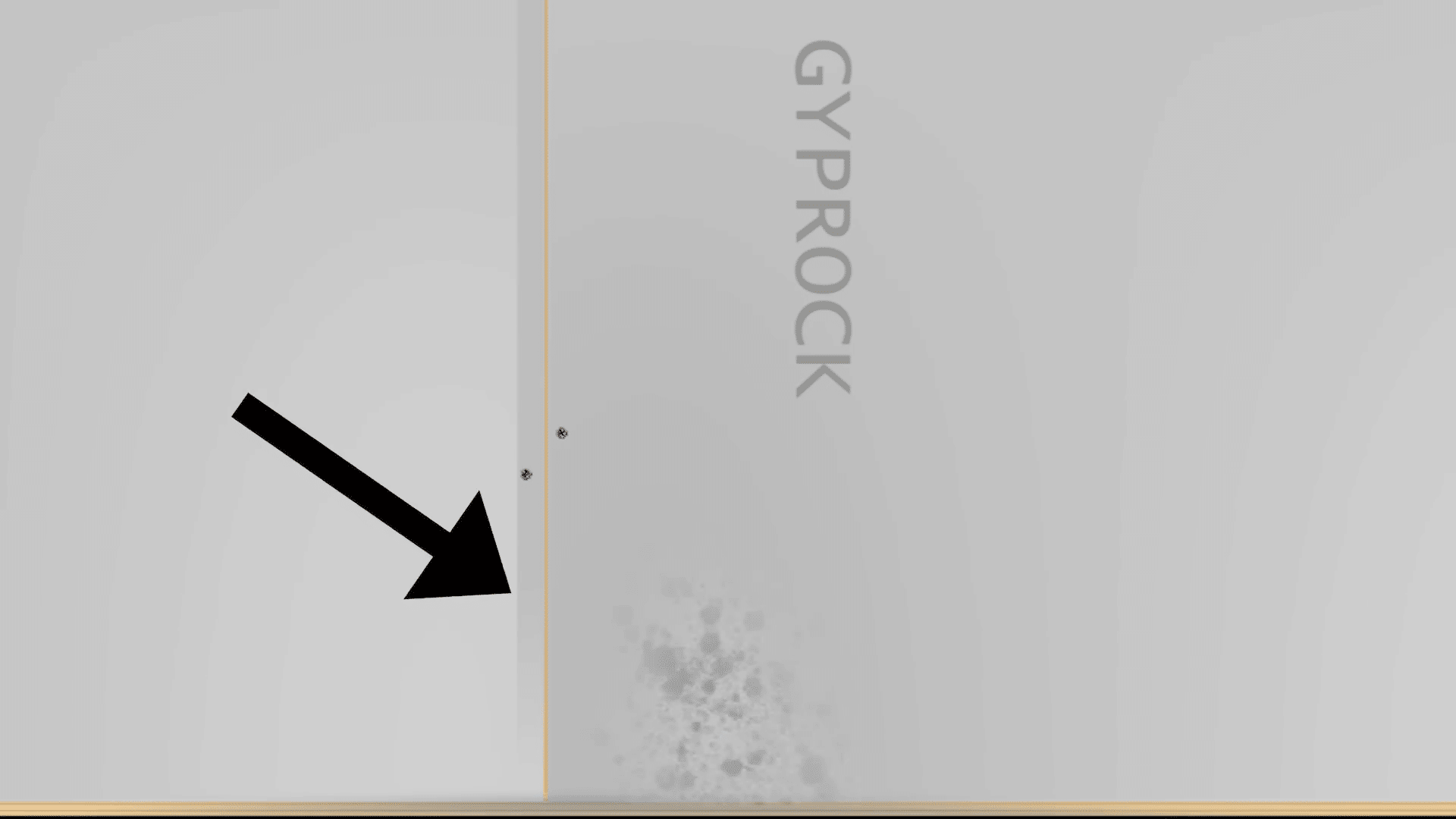

Importance of Protection Plates

Protection plates are critical yet often overlooked. These plates are installed over piping in walls to shield them from damage during subsequent construction activities, such as drywall installation. Without these plates, there’s a high risk of puncturing the pipes, potentially causing leaks that could lead to mold growth and structural damage. Installing protection plates before the inspection can prevent costly repairs and rework.

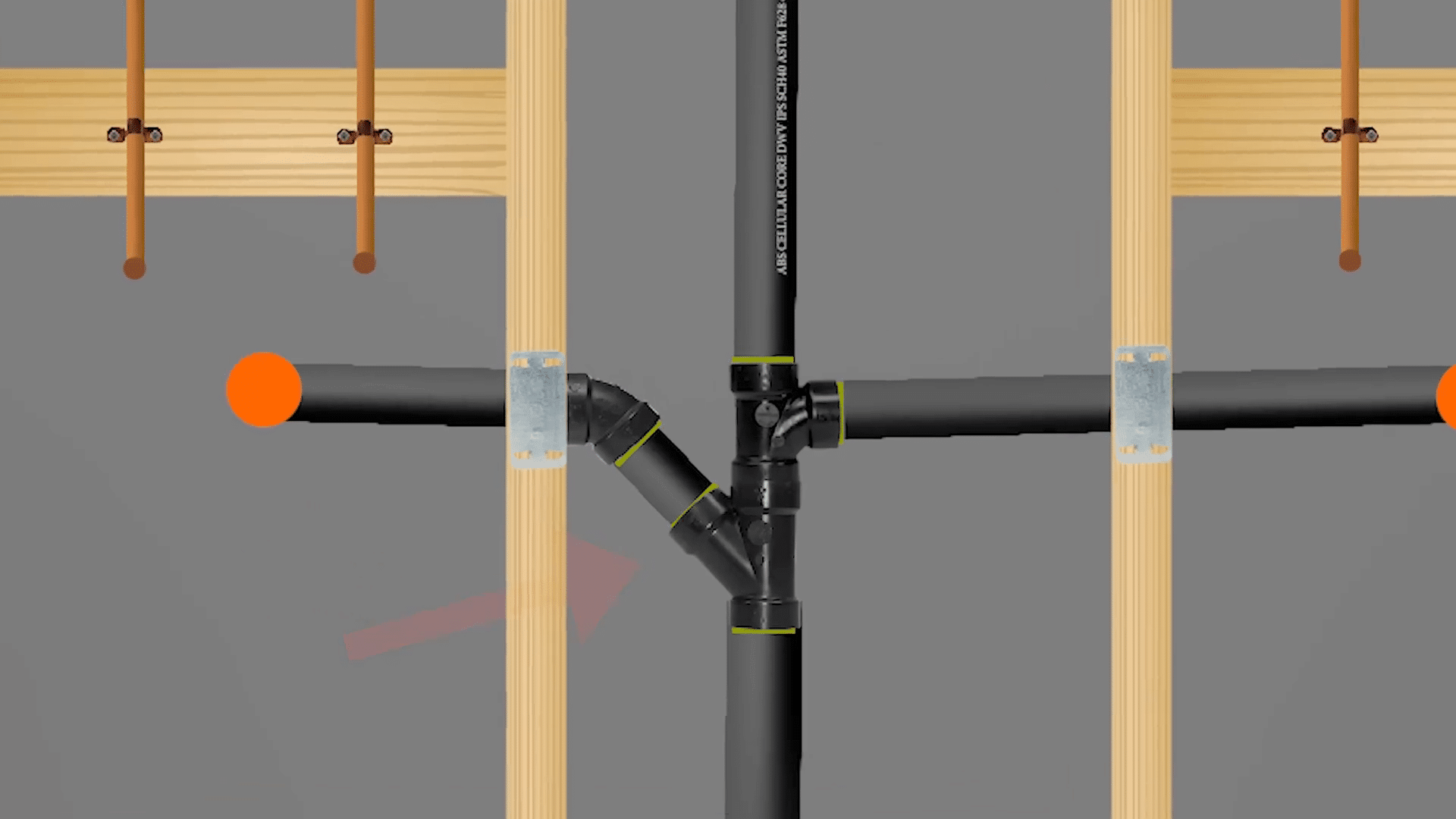

Correct Use of Sanitary Tees

Another common mistake is the misuse of sanitary tees. These fittings should only be used vertically on drain lines and can be used both vertically and horizontally for vent lines. If a sanitary tee is installed horizontally on a drain line, such as during a toilet installation, it will not comply with code due to its propensity to cause blockages over time. Instead, a combination of a Y-fitting and a 45-degree elbow should be used, which provides less resistance and reduces future maintenance issues.

Cleanout Accessibility in Main Stacks

Every main stack rising from a slab must feature a cleanout, which facilitates easier maintenance and clearing of blockages. Using a straight coupling without a cleanout not only fails to comply with code but also makes it difficult for plumbers to perform necessary maintenance. It is important to ensure that cleanouts are easily accessible to avoid extensive labor and possible damage during routine cleanings.

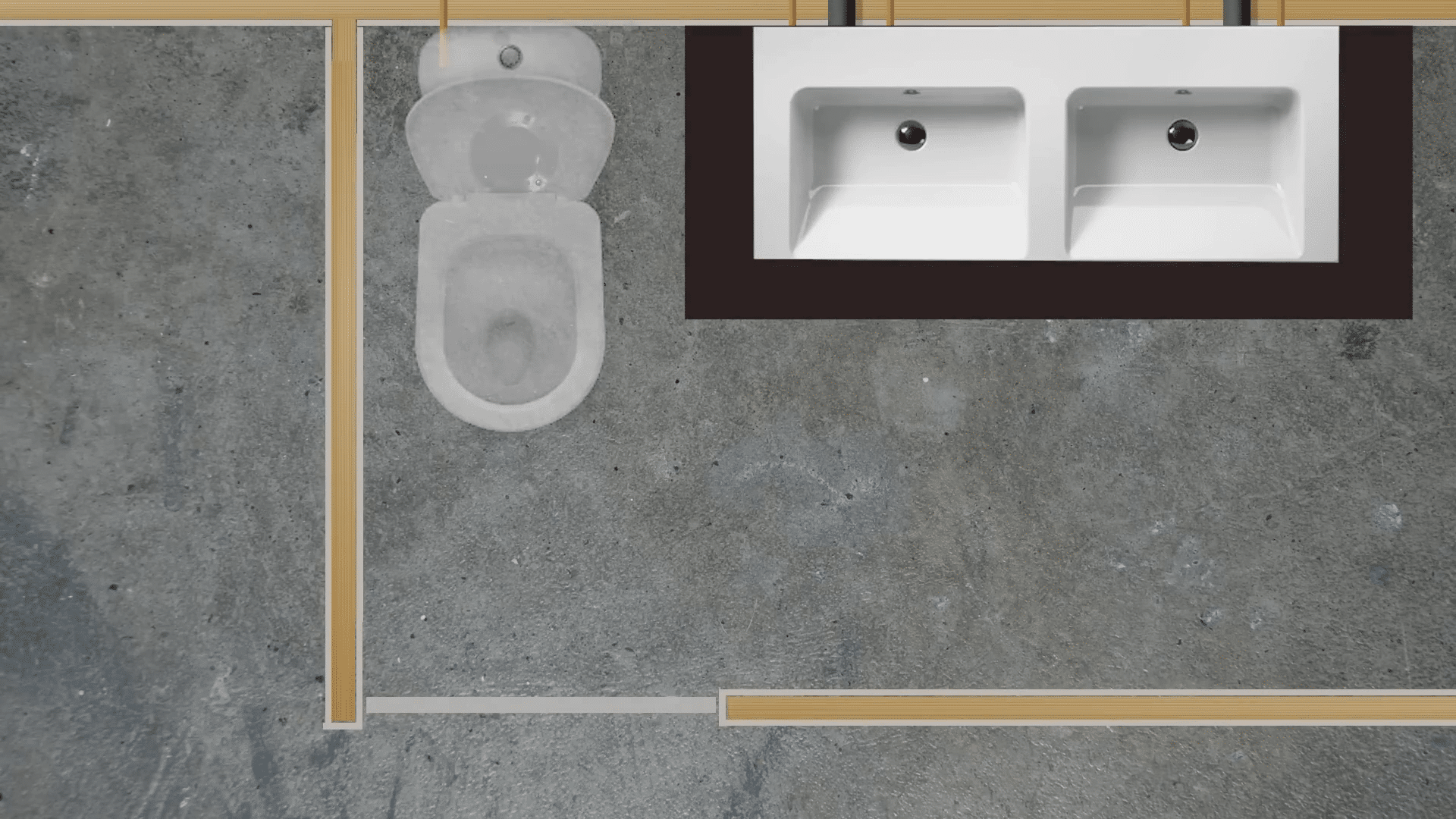

Proper Toilet Drain Placement

The placement of toilet drains is vital for both functionality and compliance. A toilet drain must have at least 15 inches of clearance from its center to any adjacent wall. Moreover, most toilets require the flange to be placed 12 inches from the finished wall to the center of the flange. Failure to adhere to these measurements can lead to discomfort in use and failed inspections, necessitating costly adjustments.

Dual Lavatory Plumbing

Incorrect plumbing of dual lavatories can lead to significant issues, such as the escape of sewer gases into a home. The configuration should allow for proper venting to prevent negative pressure scenarios where water is siphoned from P-traps. Properly using a double T-y and ensuring correct slope—no more than a quarter inch per foot—can prevent these problems. It’s also critical not to exceed the slope restriction to maintain the water seal within the traps.

Vent Positioning Above Flood Level

Vents must be installed at least six inches above the highest flood level of the fixtures they serve or a minimum of 42 inches off the ground. Incorrect vent placement can lead to sewage backup into vents instead of fixtures, eliminating any visual cues of blockage and potentially causing permanent vent blockage and damage.

Obsolete Air Chambers and Modern Alternatives

Historically, short capped pipes were installed on supply lines to mitigate water hammer—loud banging noises caused by the sudden shutoff of water flow. These air chambers would trap air that acts as a cushion against the shock. However, over time, these can become waterlogged and ineffective. Modern plumbing uses specific shock absorbers designed to handle hydraulic shocks without the downside of becoming waterlogged.

Proper Use of Drain Elbows

Drainage systems often fail inspections due to the use of inappropriate elbows. Short sweep 90-degree elbows, which are restrictive, are not suitable for drain lines and should only be used for venting purposes. For draining, long sweep 90-degree elbows or two 45-degree fittings provide a less restrictive path and are required to meet code specifications.

Structural Integrity and Pipe Installation

Preserving the structural integrity of a building is paramount when installing plumbing. Notching or drilling joists for pipe installation must adhere to specific guidelines to maintain the building’s strength. Overcutting or excessive notching can compromise a structure’s stability. When large pipes need to be installed, careful planning and adherence to building codes are essential to prevent structural damage.

Understanding these common plumbing errors can significantly increase the chances of passing inspections and maintaining efficient, safe plumbing systems. Always check the most recent plumbing codes or consult with a professional to ensure compliance and avoid the pitfalls of common plumbing mistakes.