Advancements in Concrete Construction Techniques and Structural Integrity

Home » Construction Techniques »

Progress on Concrete Construction

Continuing from where the last update left off, the construction of a new building has entered the phase of laying concrete for the ground floor walls. In construction, utilizing concrete of grade C25/30 ensures a sturdy foundation. However, the process of vibrating the concrete thoroughly is crucial to eliminate as many air pockets as possible. This is particularly challenging due to the thickness of the hose used and the presence of dense rebar, making it difficult to maneuver the hose into every desired spot.

A couple of days following the concrete pour, it was observed that while some walls were perfectly formed, others could have shown better results. The process of deshuttering, which involves the removal of molds once the concrete has hardened, provided a feeling of satisfaction, showcasing the solid, newly shaped structures. Moreover, in some areas where the walls were thinner, an additional row of bricks was required to meet the desired ceiling height, demonstrating the need for occasional adjustments during construction.

Structural Enhancements and Shuttering Techniques

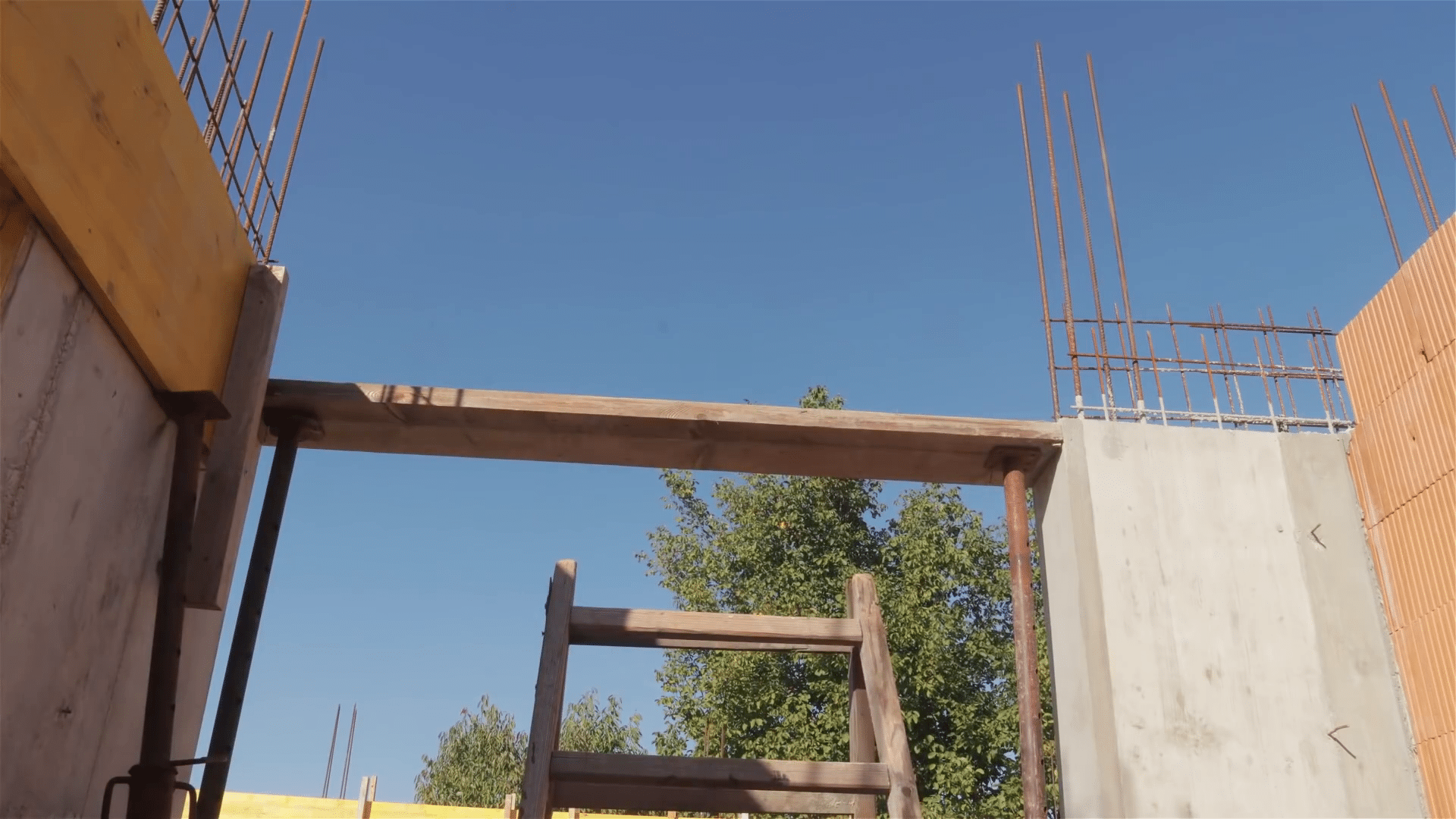

The placement of horizontal reinforced concrete (RC) bands and beams is a critical step in ensuring the structural integrity of the building. The method used here involves a simple yet effective technique for shuttering that is quick to both assemble and disassemble, highlighting the efficiency of modern construction methods. Notably, this approach requires no reinforcement on the top, facilitating an unobstructed process for subsequent concrete pours.

Once the shuttering for the bands and beams was completed, attention turned to the slab. The plan included reusing the wooden planks from this phase for later stages of the roof structure, showcasing an eco-friendly approach to construction by minimizing waste. Primary beams were constructed from nailed double planks and spaced strategically to support the structure effectively.

Reinforcement and Preparations for Pouring the Slab

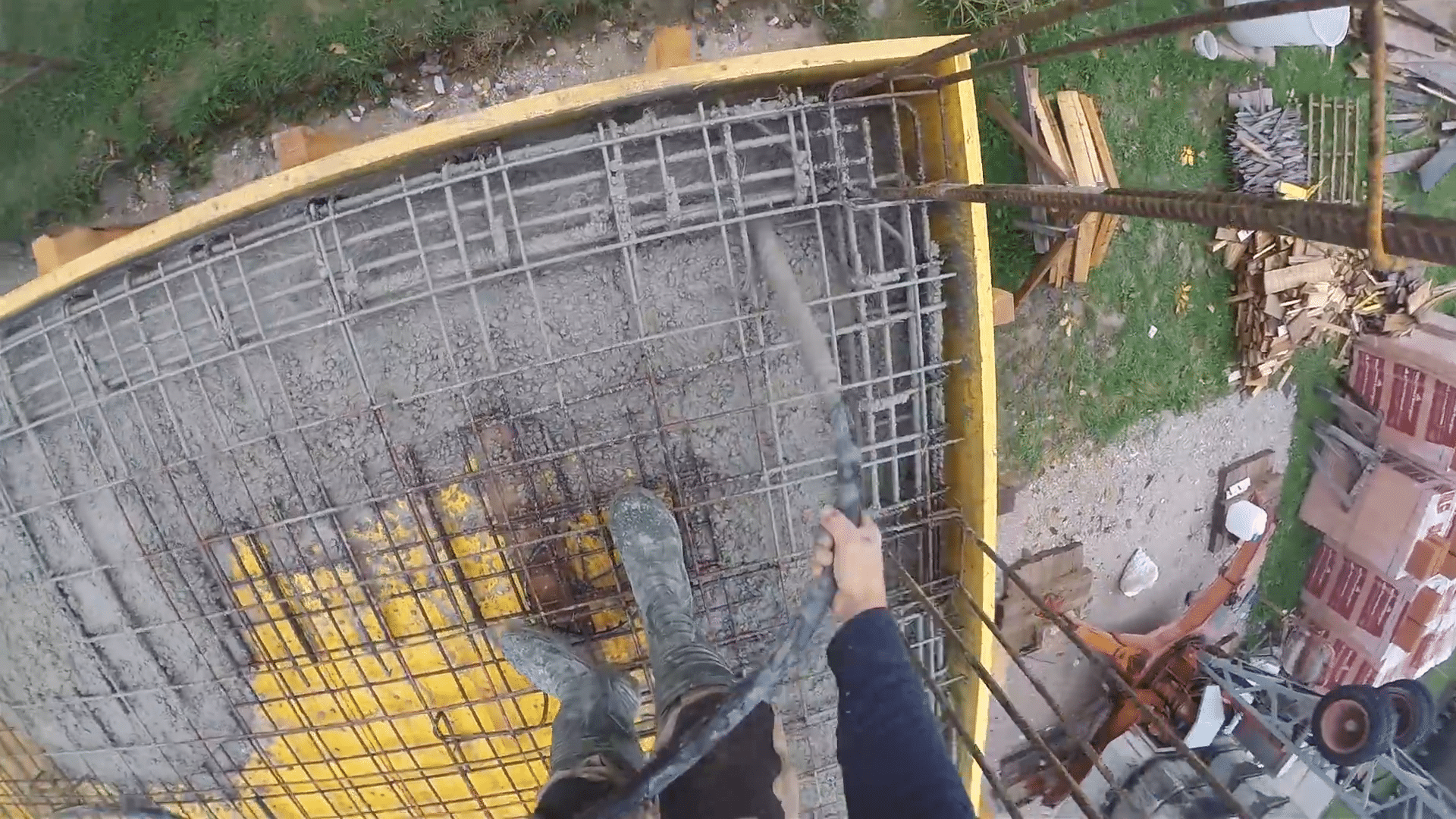

Attention to detail was paramount when placing the reinforcement for the beams and slabs. Short RC beam rebar setups involved multiple rods of varying diameters to ensure strength where it was most needed. The corner constructions were given special attention, reinforcing their importance in maintaining the structural integrity of the building. The slab mesh consisted of different grades of steel mesh for the top and bottom, providing a balanced force distribution across the slab.

Further intricacies included integrating the rebar meshes with U rebars to connect and hold both the lower and upper layers, ensuring stability throughout the structure. Before the final pour, all elements were meticulously tied together, and additional measures were taken, such as adding reinforcement around the laundry chute and ensuring all electrical and plumbing conduits were appropriately placed.

The Concrete Pour and Final Observations

The day of the concrete pour was met with perfect weather conditions, aiding in the smooth completion of this phase. The pour required precise control over the depth and spread of the concrete, with only minimal vibrations needed due to the shallow depth of the pour. Observing the concrete smoothly cover the intricately placed rebar and mesh was a testament to the expert skill level of the team involved.

The project displayed an impressive combination of detailed planning, skilled labor, and efficient use of materials. From the strategic reuse of materials to the precision in structural reinforcements, every step was taken with careful consideration to ensure durability, stability, and efficiency in the building process. The continuation of this project promises further innovative solutions and techniques in construction.

As this phase wraps up, the progress made not only reflects the hard work of the team but also hints at the modern construction practices that can be expected in future updates. The blend of traditional techniques with modern engineering solutions continues to push the boundaries of what is possible in construction today.