Unlocking the Secrets of Vapor Barriers: Roles, Misuse, and Best Practices in Building Construction

Home » Construction Techniques »

Understanding the Role and Misuse of Vapor Barriers

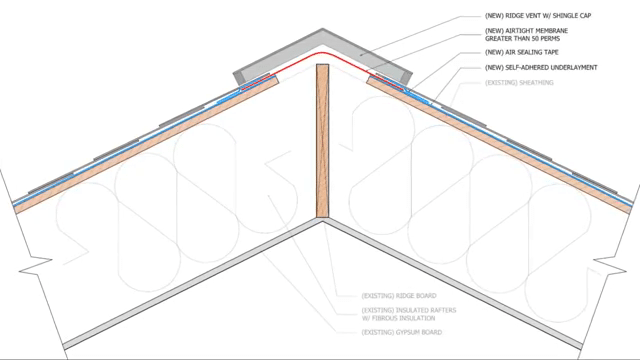

Vapor barriers, or vapor retarders, are critical components in building construction designed to manage moisture, thereby protecting the building from potential damage such as mold growth and structural rot. Contrary to the common assumption that a vapor barrier simply blocks moisture, its actual function is to regulate moisture diffusion within building assemblies. This is crucial in preventing condensation on cold surfaces which may lead to higher humidity levels and, consequently, deterioration in building durability.

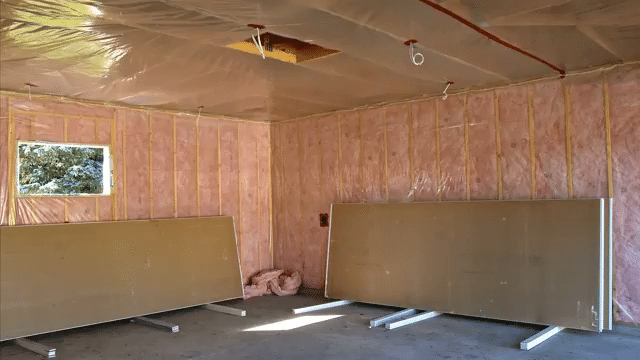

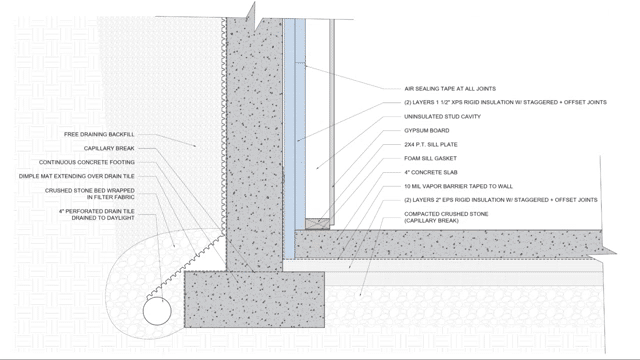

Moreover, vapor barriers serve as capillary brakes to prevent moisture from wicking into building materials, like in slab-on-grade constructions. Understanding how moisture behaves according to the second law of thermodynamics—moving from higher to lower concentrations and from warm to cold areas—is essential in comprehending why and how vapor barriers work. However, if vapor barriers are punctured or incorrectly installed, they may not function effectively as air barriers. This can lead to significant issues since air leaks can transport moisture much faster than diffusion, leading to trapped moisture and associated problems.

Classes of Vapor Retarders and Their Applications

Vapor retarders are categorized into three classes based on their permeance. Class I vapor retarders, such as standard polyethylene and foil-faced insulation, have a permeance of less than 0.1 perms and are highly resistant to vapor diffusion. Class II, which ranges from 0.1 to 1 perm, includes materials like unfaced rigid insulation (XPS, EPS). Class III vapor retarders have a permeance between 1 and 10 perms and include materials such as OSB and latex paint. Materials with a permeance over 10 perms are considered vapor-open or permeable, offering less resistance to vapor passage.

Interestingly, there are vapor-variable materials which exhibit different permeance under varying conditions. These materials, such as smart vapor retarders and certain types of plywood, adapt their permeability based on the ambient humidity, thus offering more flexibility in managing moisture in building assemblies. They allow for the slow release of moisture, preventing condensation while still permitting drying, which is crucial in maintaining the structural integrity of the building.

Moisture Management in Different Building Assemblies

In colder climates, such as in Canada, it’s common to install vapor barriers on the interior side of wall assemblies to manage condensation. However, this can lead to issues during seasonal changes. For instance, during warmer months, moisture driven from the exterior can become trapped within the wall cavity by the vapor barrier, especially if the interior is air conditioned. This trapped moisture can condense, leading to water absorption by framing materials and potential mold and rot at the base of the walls.

To prevent such scenarios, alternative strategies include using exterior rigid insulation to warm the sheathing, thereby preventing condensation, or opting for smart vapor retarders that adjust their permeance based on the humidity levels within the wall cavity. This adaptability allows the assembly to dry out, rather than trapping moisture indefinitely.

Challenges with Basement and Crawl Space Moisture

Basement walls present unique challenges due to their below-grade placement. Often, improper installation of vapor barriers on the interior side of basement walls can trap moisture, leading to mold growth. Instead, solutions such as taped rigid foam insulation or closed-cell spray foam applied directly over the concrete walls are recommended. These materials act as both vapor retarders and air barriers, preventing condensation from moisture-laden interior air. Additionally, implementing a capillary break at the footing can prevent moisture from wicking up into the concrete from damp soils, complemented by good drainage practices to divert water away from the foundation.

Crawl spaces are another area of concern, particularly in vented designs. Placing a vapor barrier directly over the ground can prevent moisture evaporation into the home. However, in humid climates, moisture can still enter the crawl space and condense on the underside of floor framing. Using foil-faced rigid insulation as an air and vapor barrier can effectively separate the floor framing from the crawl space environment.

In conclusion, while vapor barriers are integral to protecting buildings from moisture-related issues, their misuse or incorrect installation can lead to significant problems. Understanding the specific needs of different building assemblies and using the appropriate types and classes of vapor retarders can provide effective moisture management, ensuring the longevity and durability of structures. For those interested in deeper insights and comprehensive guidance on building envelope design, further resources are available that cover a broad spectrum of topics related to building science and practical implementations.