Steps for Preparing and Constructing Foundations

Home » Structural » Foundation »

Laying the Foundations: From Marking to Gravel Compaction

The initial step in preparing for the construction involves setting up the posts for what will become the foundational walls. The posts are first hammered into the ground and marked at the same elevation that will correspond to the finished ground floor. Planks are then screwed onto these markings, ensuring they are perfectly level.

Following this, a string is lowered to each small surveyor post. These posts, which were placed by a licensed surveyor a few days earlier, mark the corners of the foundations. The string is pulled to touch the vertical strings, and where it touches the plank, a mark is made. Small screws are then fixed onto these markings to enable strings to be pulled between them, delineating the area where the topsoil must be removed.

Preparing the Ground: Topsoil Removal and Gravel Layering

The next task involves removing the topsoil within the marked area, including an additional one-meter offset from the foundations plus the space for the driveway. This typically involves removing 20-30 cm of topsoil. Once the topsoil is cleared, a geo-textile membrane is placed over the area. This membrane prevents the different layers of soil from mixing and increases the ground’s load-bearing capacity.

Subsequently, a considerable amount of gravel is spread over the area. Strings are once more pulled to mark the foundations, and posts are hammered where the strings intersect, marking the corners of the foundations. Additional posts are added in between to make it easier to outline the exact foundation layout. The gravel is then compacted to ensure a stable base for the foundation dig.

Digging the Foundations and Rebar Placement

Excavation for the foundations begins after the gravel is compacted. The foundations will rest on a 30 cm thick compacted gravel layer. A crane, borrowed from another construction site nearby, assists with heavy lifting. This crane has an 18-meter reach, a 1-ton load capacity at 10 meters, and a 600 kg capacity at 18 meters.

The rebar arrives next. The foundations will be reinforced with five 14 mm rods at the bottom, five 14 mm rods at the top, two 10 mm rods in the middle, and 8 mm stirrups every 25 cm. The level of compaction is tested using a deflectometer to ensure it meets the required standards.

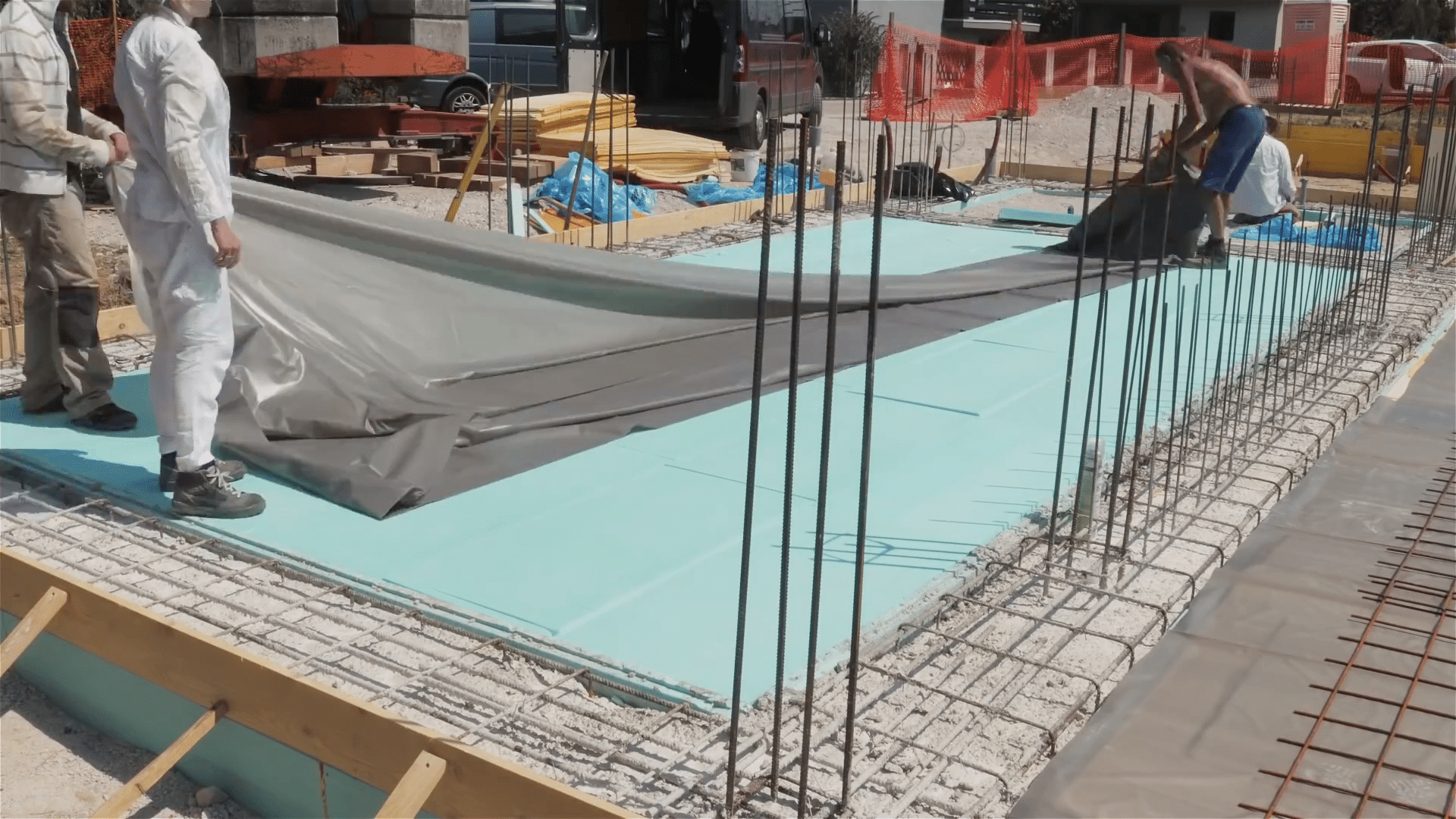

Setting Up Vertical Rebar and Insulating Foundations

Vertical rebar anchors for the reinforced concrete (RC) posts and walls are then placed. For shuttering and insulation, 5 cm of extruded polystyrene is used. Wooden stakes keep the shuttering at the correct distance and will be removed during the concrete pour. The top part of the polystyrene is reinforced to withstand the pressure of the concrete, preventing it from breaking.

An exception is made for the tool shack foundations, which do not require insulation, so no polystyrene is used there. Finally, the concrete arrives for the first of many pours. The concrete used is C25/30 grade, known for its strength and durability.

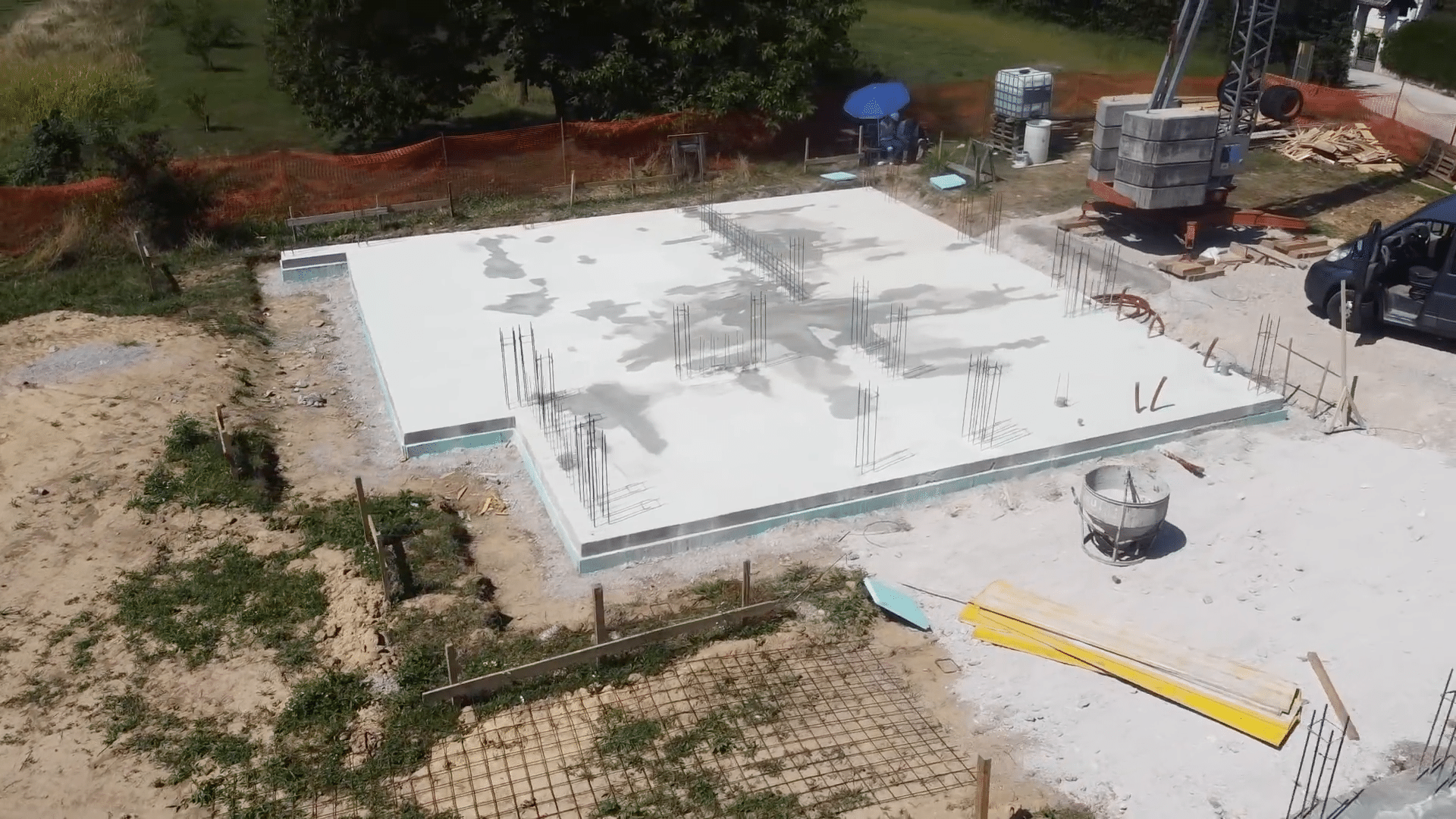

Pouring Concrete and Final Adjustments

During the concrete pour, wooden stakes are pulled out and the concrete is vibrated to remove any air pockets. The wooden reinforcements are also removed at this stage. The excess polystyrene is then cut to a level plane, marking the bottom level of the slab.

The space between the foundations is filled with gravel, which is compacted until it is 8 cm lower than the desired level. Slab shuttering is then placed, and the level of compaction is tested again. The 8 cm height difference is filled with polystyrene to insulate the slab’s bottom.

Final Preparations for the Slab

Q257 rebar meshes are laid down to provide additional reinforcement. In the left corner, water and electricity pipes are visible, although their installation was not captured on record. Concrete blocks are placed to maintain the correct distance between the bottom and top rebar meshes.

On the day of the slab pour, the slab is formed to a thickness of 14 cm. This concludes the foundational phase of the construction project, setting the stage for the subsequent building activities.

All these steps—from setting up posts to pouring the concrete slab—are crucial in ensuring a strong, stable, and well-insulated foundation. Each phase requires precision and careful planning to guarantee the structural integrity of the completed building. Ensuring that the ground is well-prepared and the materials are of high quality will contribute to the longevity and durability of the structure.