Replace a Missing Main Breaker on Electrical Panel

Home » Electrical » Electrical Panels »

Electrical Panel Installation on a Warm Morning

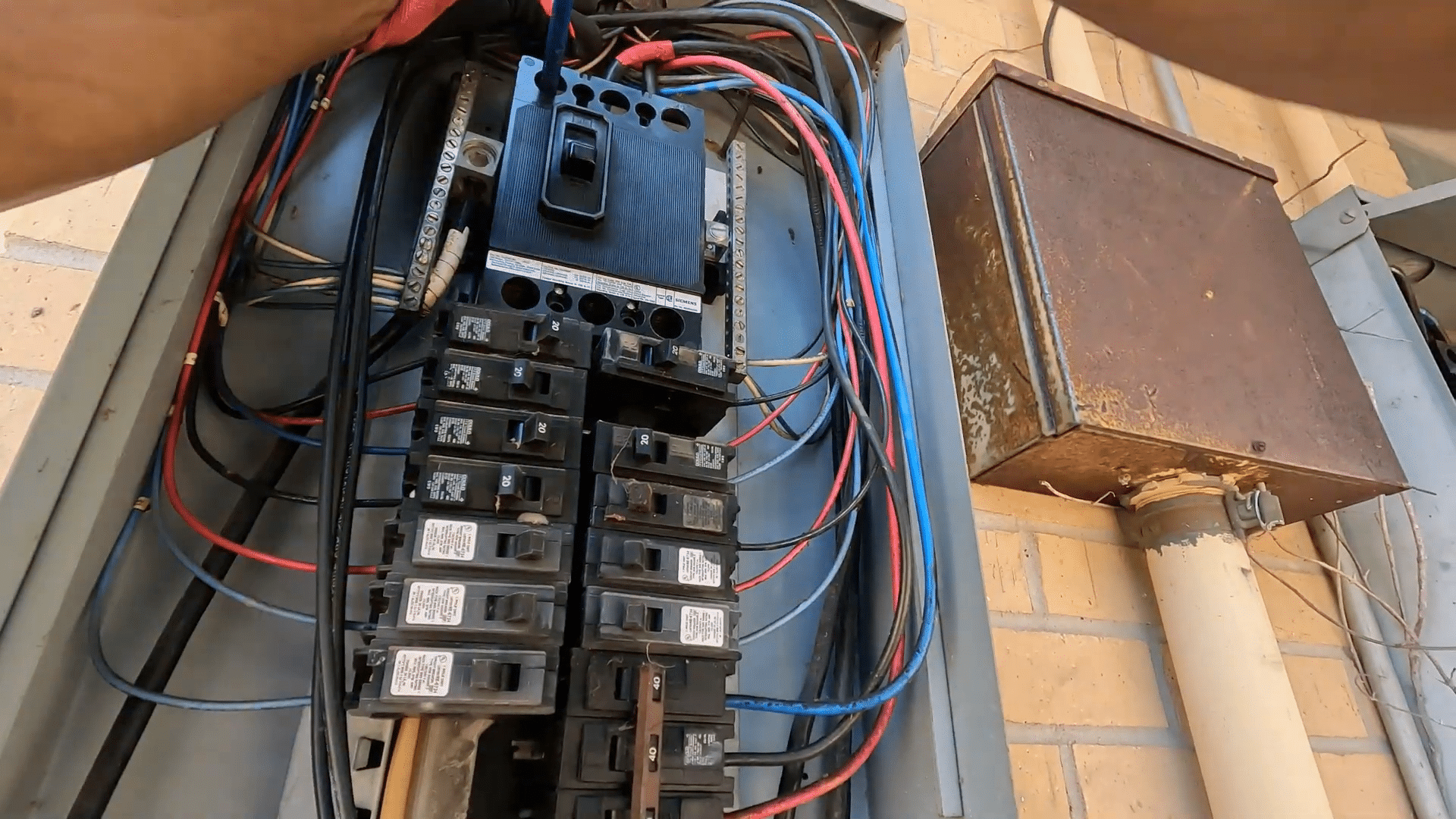

On a beautiful morning with temperatures slightly above 80 degrees, an electrical job presents itself with a missing main breaker in one of the building’s panels. The absence of this crucial component might be attributed to theft or it simply might have been removed and never replaced. Regardless of the cause, the building’s power cannot be activated without it.

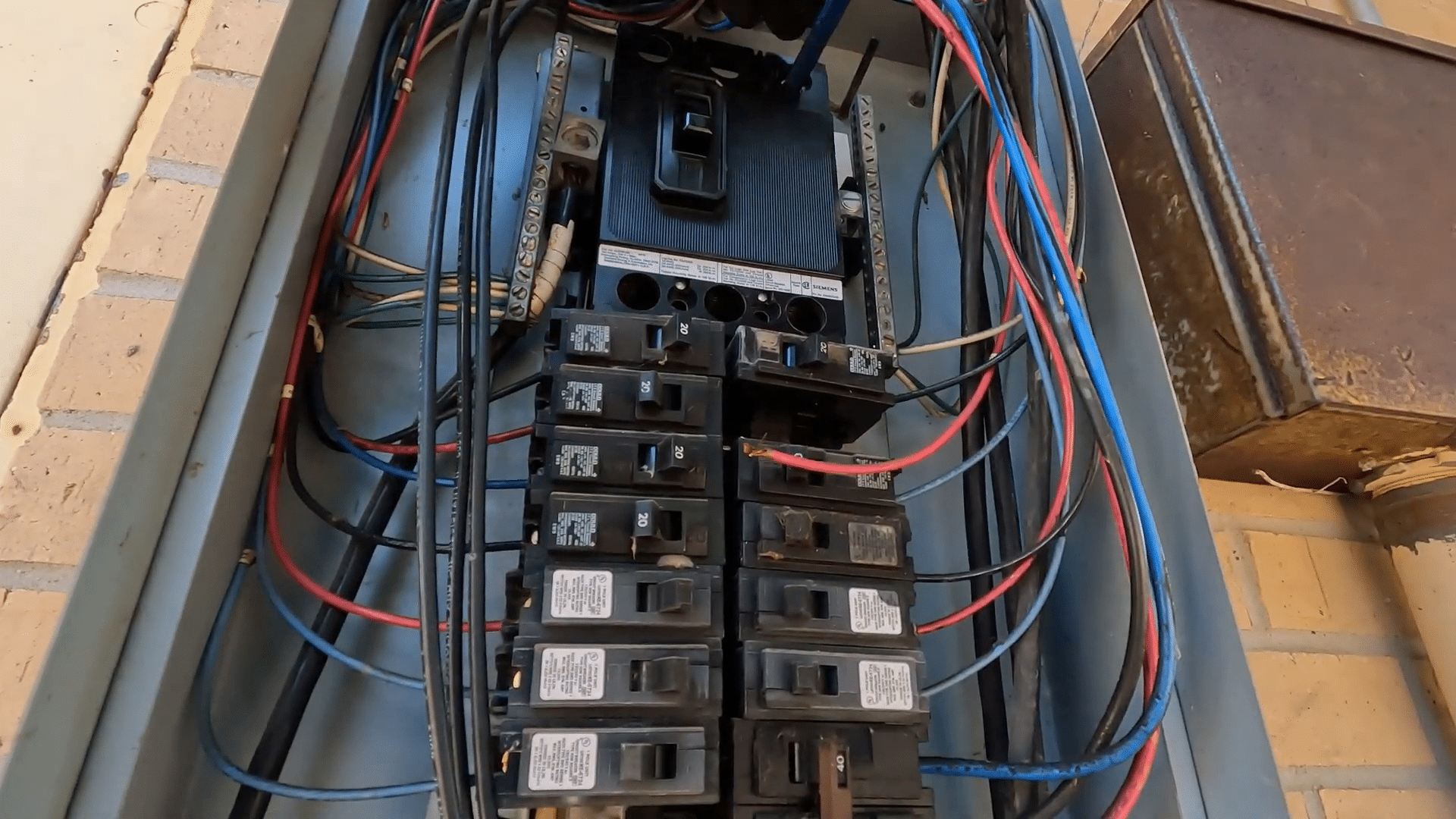

Identifying the Missing Part

Upon inspection, the space for the main breaker in the panel is found empty. This vacancy is noticeable from the line wires feeding into the panel. The replacement task requires an understanding of both residential and commercial electrical systems, as they sometimes have different configurations, such as bolt-in breakers which are common in larger commercial buildings.

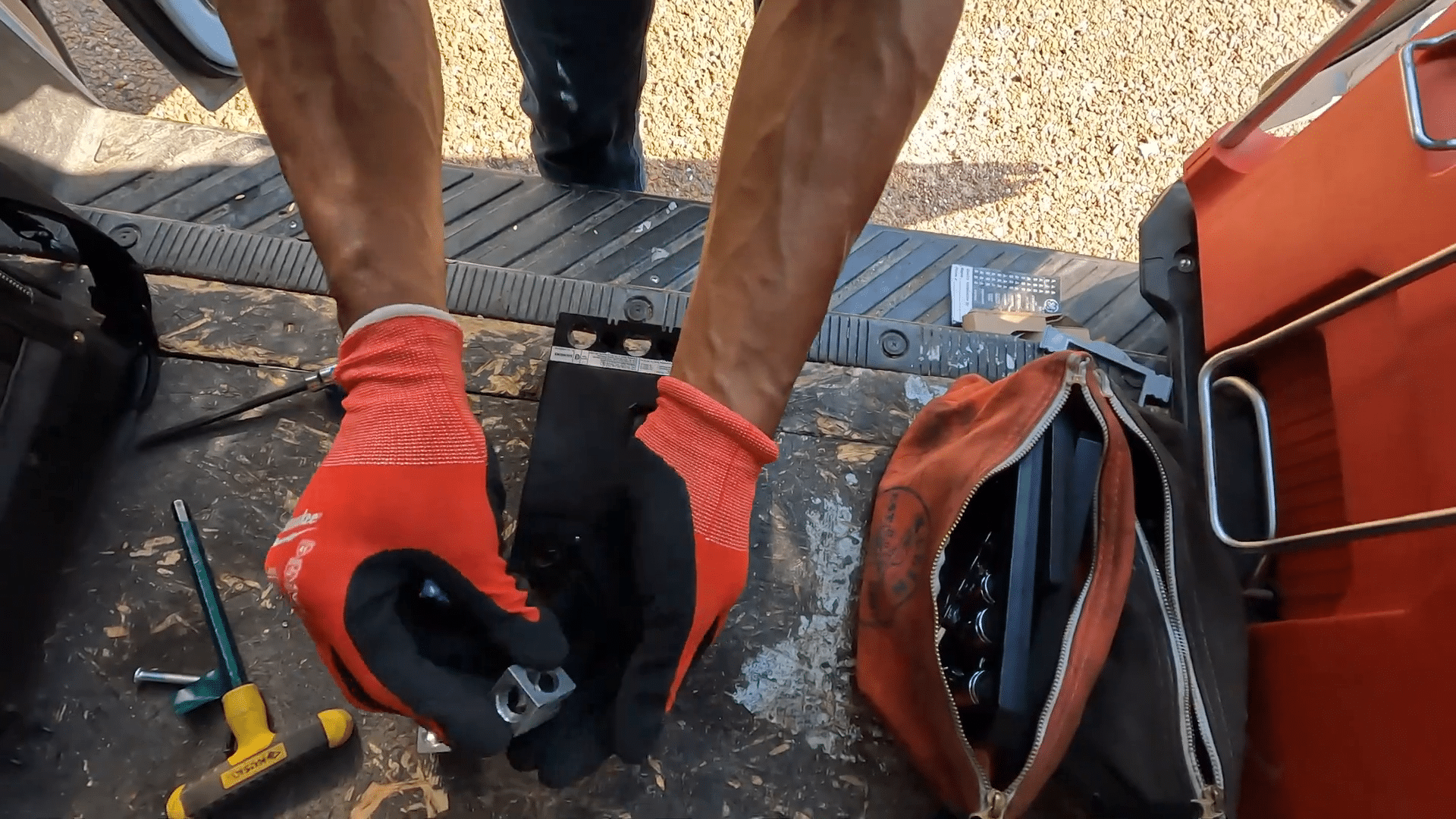

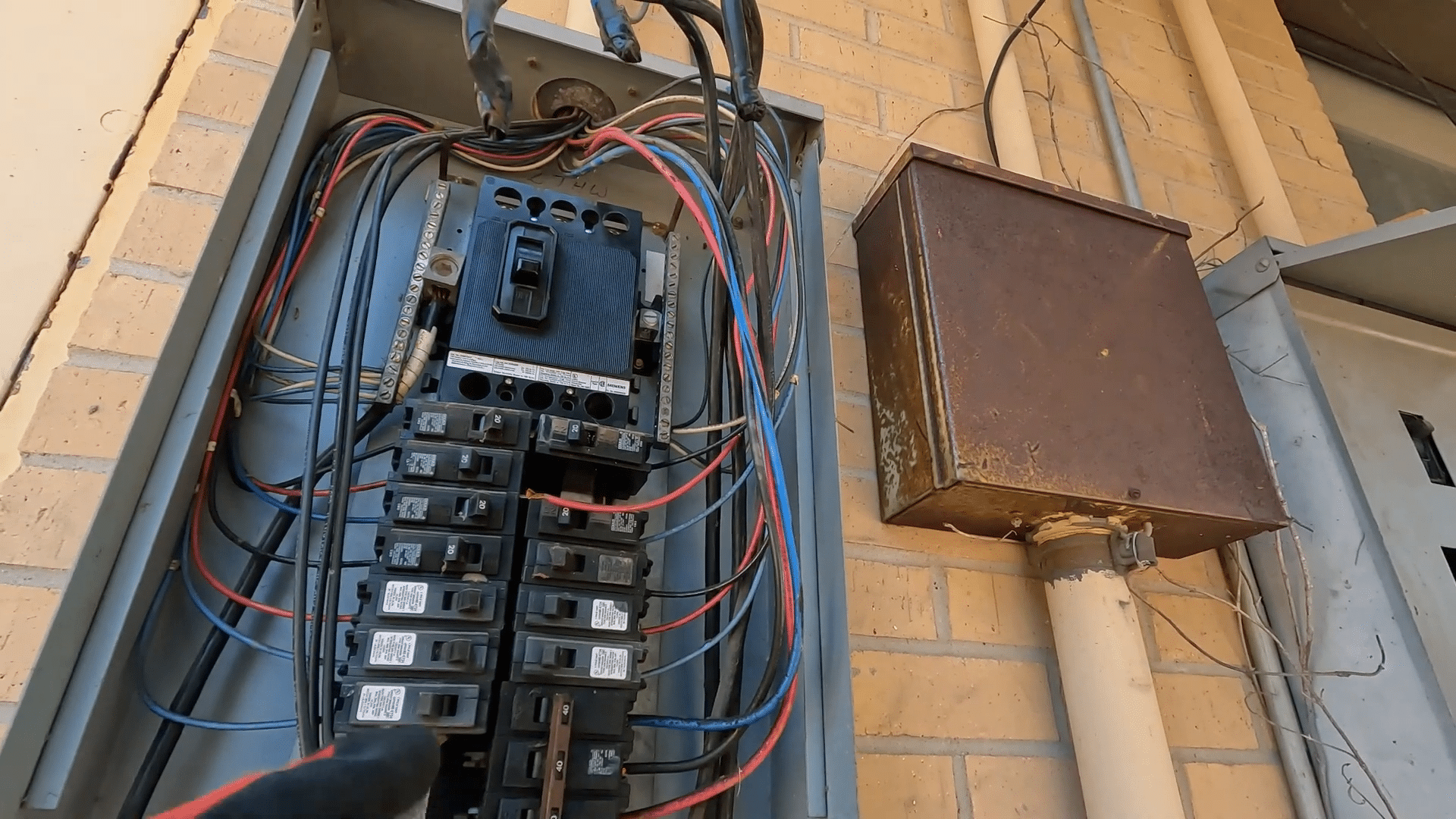

Preparing the Breaker for Installation

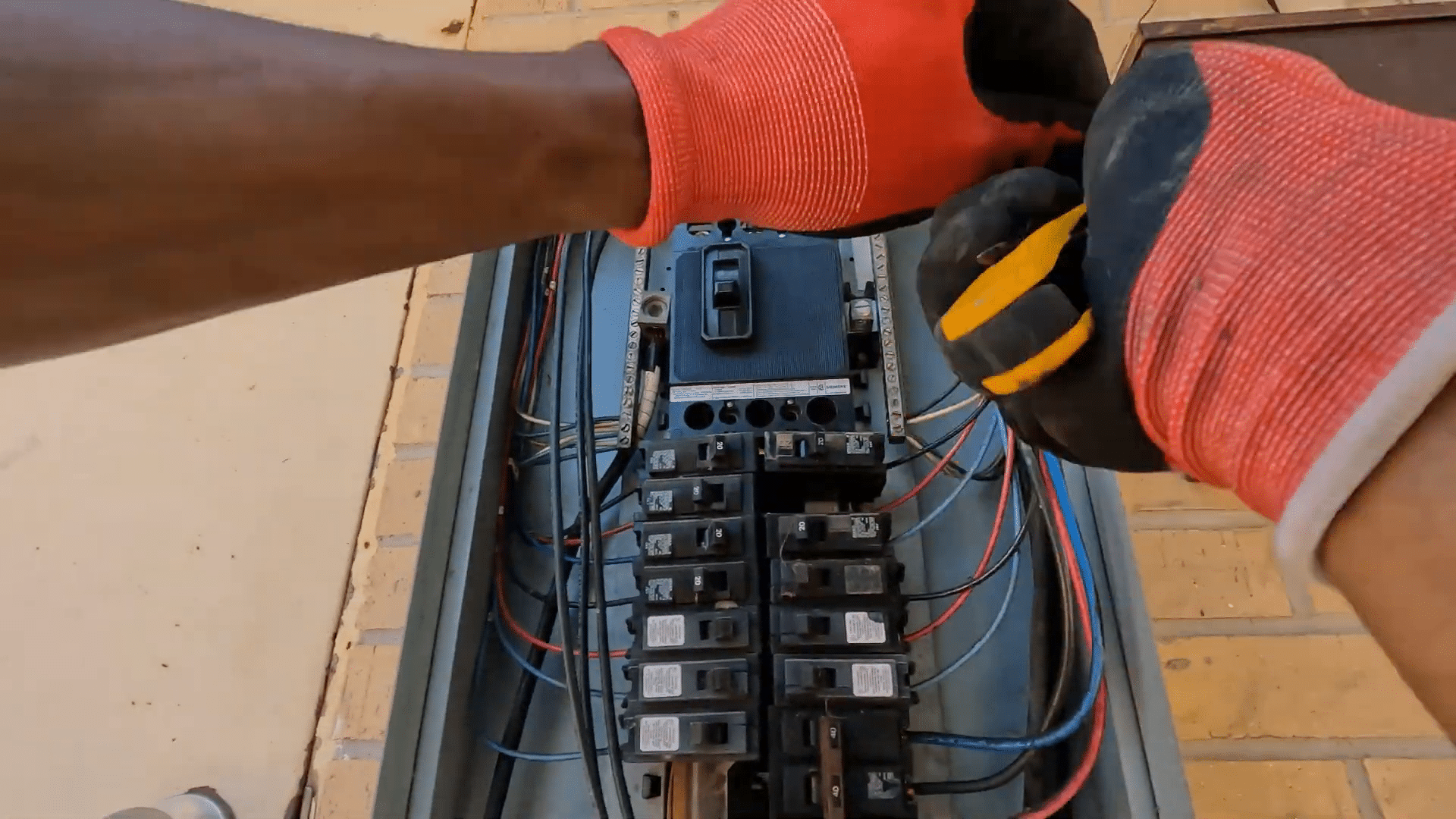

The main breaker identified for this job is a bolt-in type. Observing the setup, it is clear that the configuration needs to be adjusted. The feed wires enter from the top, while the current breaker setup is configured for a bottom feed. Therefore, the Allen lugs positioned at the bottom must be relocated to the top.

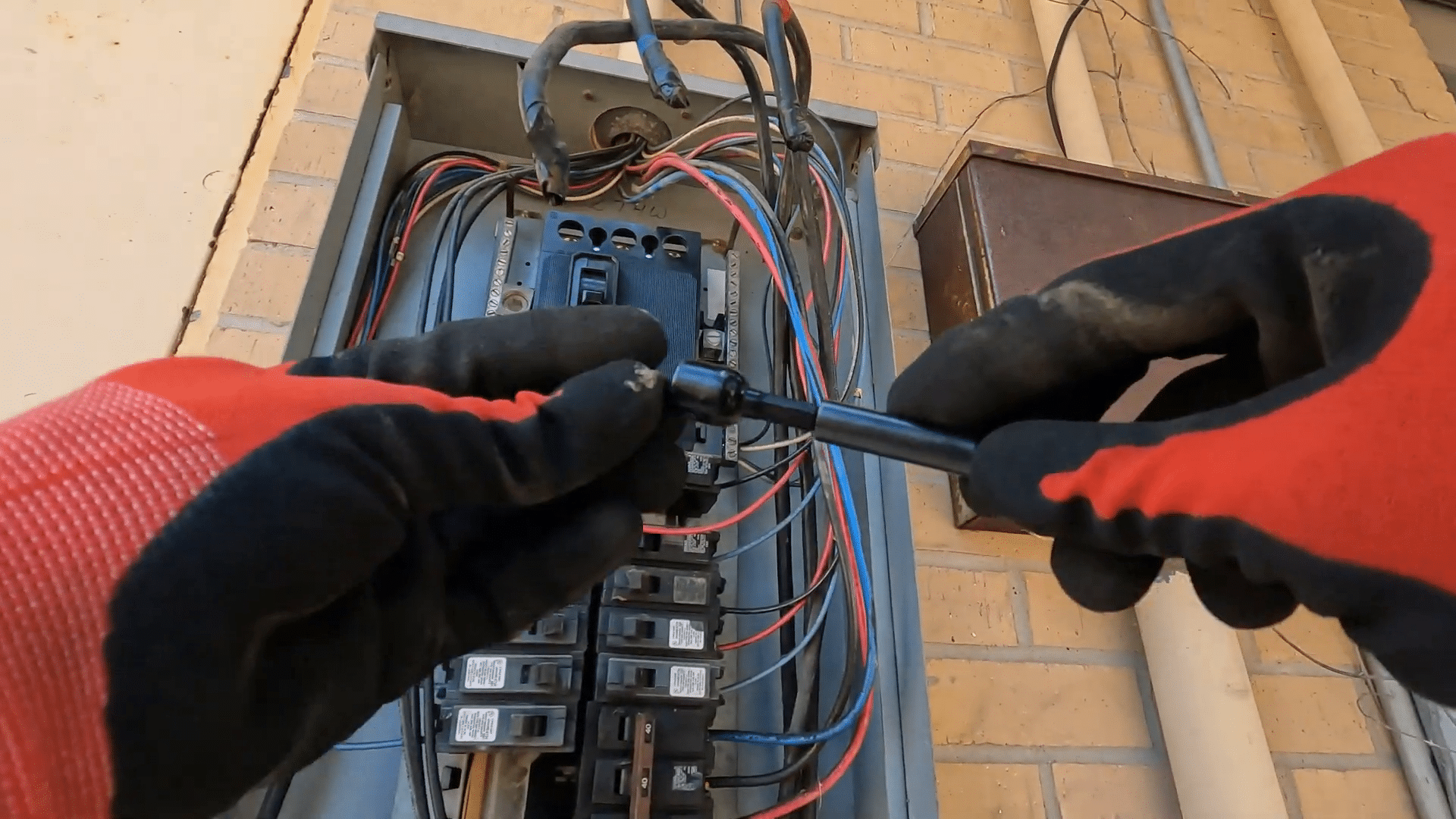

Disassembling and Reconfiguring

To access the bolts holding the breaker, the Allen lugs need to be removed. After unscrewing the bolts, the lugs are repositioned to the top of the breaker. This process is done carefully to avoid any damage or cross-threading of the components. A torque setting of 150 inch-pounds is required for the mounting screws, which translates to 12.5 foot-pounds using a torque wrench.

Ensuring Proper Torque

With the torque wrench set correctly, the bolts are tightened to the specified torque. A temporary mark is applied to ensure that if anyone tampers with the bolts later, it will be evident.

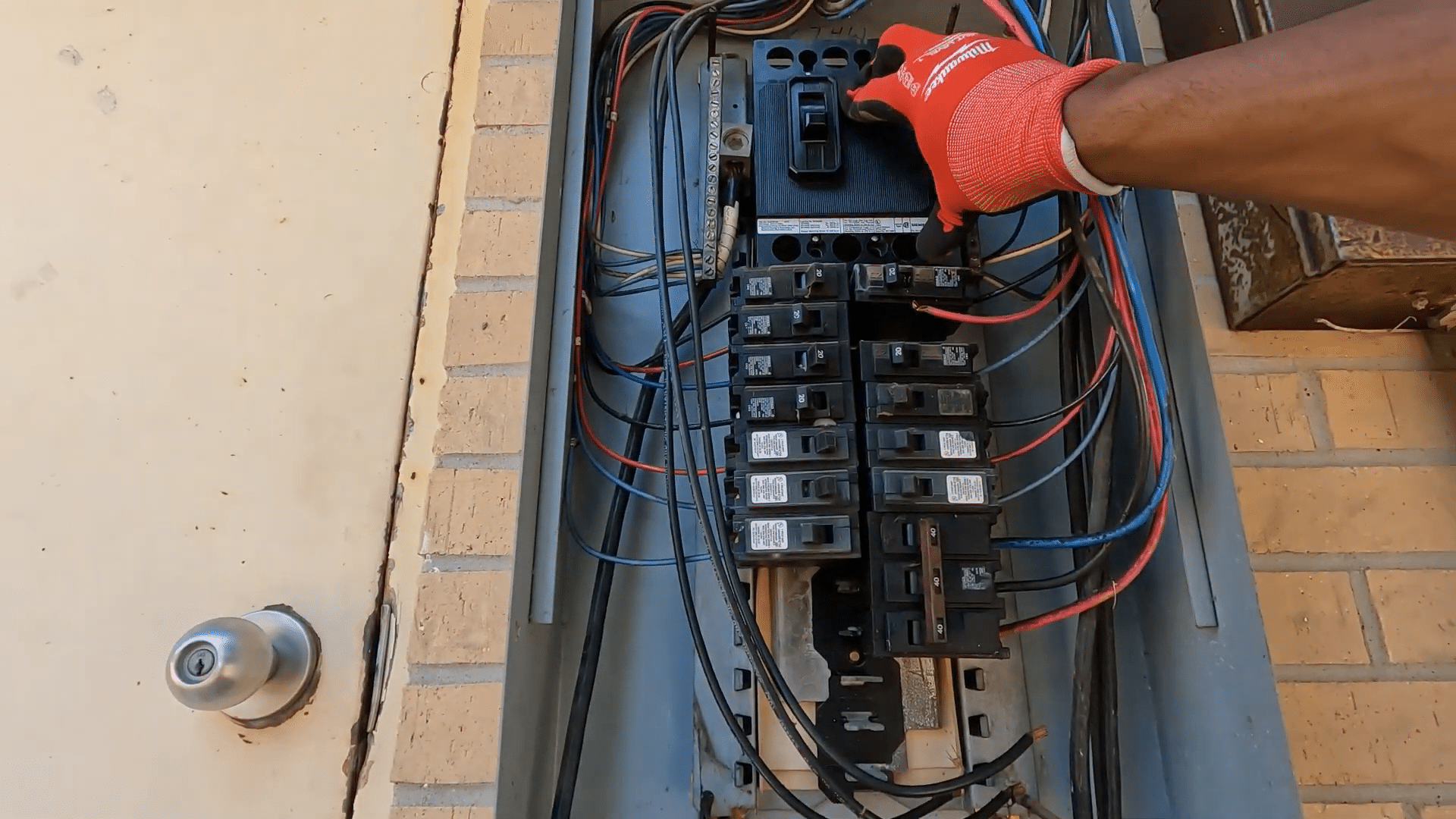

Removing the Panel Cover

To make the installation more manageable, the cover of the panel is removed, providing more space to work. This step is crucial in ensuring that all connections are made securely and without strain.

Installing the Breaker

Using a shallow socket, the nuts are installed onto the bolts. This shallow socket ensures the nuts stay in place without falling through the tool. Once positioned correctly, the bolts are tightened to 12 inch-pounds.

Checking for Power

Before proceeding, a power check confirms that the panel is safe to work on. With no power present, the lugs are put back in place and torqued to 200 inch-pounds, converting to the necessary foot-pounds for the torque wrench setting.

Connecting the Wires

The wires are inserted into their respective positions in the breaker. Standard color coding is followed: black, red, and blue. Each wire is inserted carefully to ensure a secure connection. The wrench used for tightening the connections breaks, necessitating the use of a backup tool to complete the job.

Final Torque Settings and Seals

The torque wrench is set to 16 inch-pounds for the final tightening of the wire connections. After securing the wires, seal marks are applied once again to indicate any future tampering. Although proper torque seal should be used, a temporary mark suffices in the meantime.

Importance of Proper Installation

Proper installation of electrical components is crucial for safety and functionality. Misconfigurations or improper torque settings can lead to electrical faults, potential fire hazards, or equipment damage. Electricians must be diligent in following protocols and ensuring all connections are secure.

Preventive Measures

To prevent issues like missing components, regular inspections and maintenance are essential. During inspections, electricians should check for any signs of tampering, wear, or damage. Using proper seals and documenting any changes made can help in maintaining the integrity of the electrical system.

In conclusion, the task of replacing a missing main breaker involves careful planning, proper tool usage, and adherence to safety protocols. Ensuring that all connections are tight and correctly configured is paramount to restoring and maintaining the building’s electrical power. Regular inspections and preventive measures can help avoid similar issues in the future, ensuring a safe and reliable electrical system for the building.