Why are we still cutting grounds so short on new construction with 312 deep boxes when it causes issues and extra work for troubleshooting?

11 months ago

Last Updated: August 7, 2024

What’s the deal with cutting the grounds so short on new construction with 3-1/2” deep boxes? It’s just something that bugs me, especially when there’s a problem and I have to yank out a box for troubleshooting. I know it used to be necessary back in the day when boxes were smaller, but why still do it now?

I still have the codes and will use them if needed. They’re still more valuable than useless wegos.

Do you also cut the grounds really short and twist them all the way to the back of the box?

I usually cut them a bit longer than the box. And yes, only with the grounds. I think it’s required by code if you use them. I’ll have to look it up. But that’s how I was taught as well. 😂

If you were working on a house remodel or troubleshooting, would you prefer to deal with a box where the ground wire is very short and twisted, or one with plenty of extra slack?

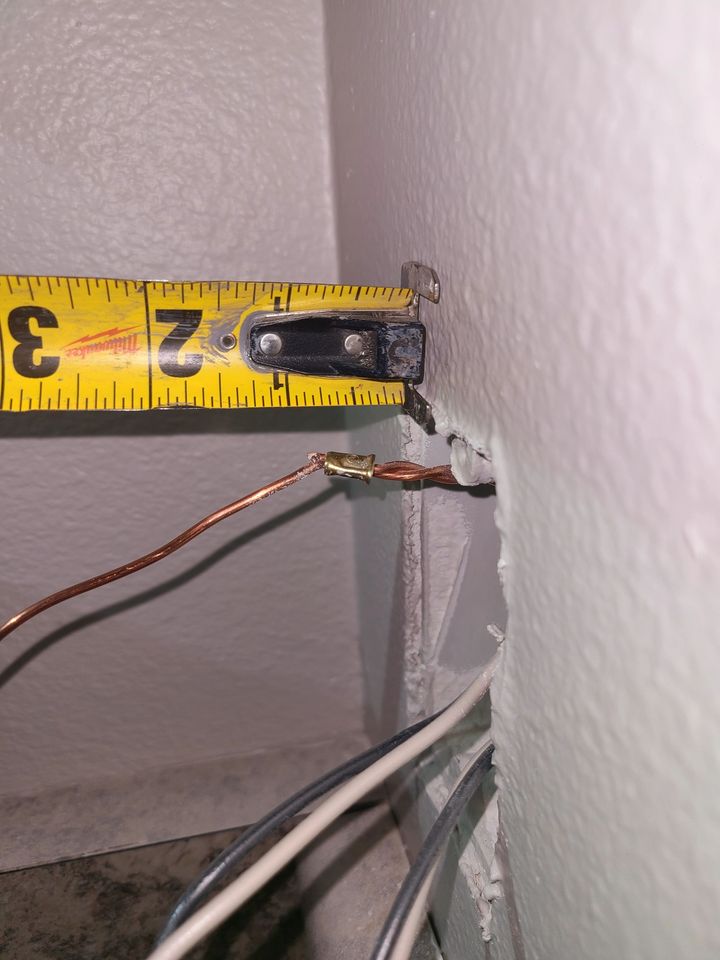

This install violates code

Ever heard of NEC 300.14?

Um that is for conductors

Just to clarify, the crimp is considered a splice, and the shorter conductor is essentially being extended by the longer one it’s connected to.

The 2023 NEC actually got updated to allow splicing of the required free conductor. This change was aimed at addressing existing installations where conductors were shortened during device replacements. It wasn’t meant to encourage sloppy work in new installations. Would you intentionally cut both grounded and ungrounded conductors to 2 inches and then splice a pigtail? Technically, it might pass 300.14… Oh, and let’s not forget about 110.12. I wouldn’t hesitate to call out this subpar work.

So, according to your point, there’s no limit to how long you can cut any conductor in a box? Is cutting it to 1 inch okay, as long as you can splice it properly? Sounds like a bit of a hack logic to me.

Just a heads up – grounds are not considered conductors. I always keep my wires at 6 inches, even the grounds.

Hey, talking about equipment grounding conductors here.

Hey, it’s not my argument. It’s all about the code. If you’re not a fan of it, suggest a change to the code-making panel. The code sets a minimum standard, but we can always strive for better. By the way, I highly recommend watching Mike Holt’s DVDs. They are definitely worth the investment of both money and time. You’ll gain a lot of knowledge and elevate your understanding of the code.

To be compliant with the code, you’d have to splice onto each conductor individually to have each one extend 3″ past the box. Joining multiple conductors into one and then extending it doesn’t count as free length for all conductors, that’s just a standard pigtail procedure.

The way you’re understanding the code, it would be practically useless and meaningless.

I’m not “interpreting” anything. The length extending out of the box should be 6”. Even if there’s a splice in that conductor, it’s still following the code. Would I personally do that? No. Is it code-compliant? Yes.

You raised the question, and I’m giving you an answer. They do it because it’s permitted. If you’re not a fan, it’s irrelevant.

Why are you taking out boxes for troubleshooting? In what situation would having longer free conductors spare you from box removal?

Bad electricians passing on bad practices. Using wire nuts and pigtails. round crimps are a sloppy shortcut.

Definitely not slacker!

The ground connected to the device is NOT CUT.

NO RISK OF FAILURE

If that ground isn’t making proper contact with the neighboring grounds, you’ll end up with some unconnected components.

Here’s another one from the same site, but it seems like a different electrician. Is the crimp without twists good enough? That third wire must connect to something, and if it’s not making solid contact, you’ll definitely lose grounding somewhere.

I’m pretty sure that any type of connection can go wrong if you try hard enough, but they can all be done correctly with care. Some are just more of a hassle for the next person.

This photo is a terrible installation.

If you really like wire nuts, they do make green ones that don’t need the ground to be cut!

Why does it matter if the ground wire the device is connected to is continuous? The entire grounding system relies on strong connections to function properly.

I opt for regular wire nuts because I can install them quickly with the drill attachment. They all serve the same purpose.

You’re not taking your work seriously.

Educate yourself on “continuous ground”

And “Irreversible ground”

The most basic thing in residential settings is a whirlpool bath tub.

If you’re not knowledgeable about grounding… refrain from making comments about it

It’s a weak point 🤦♂️

It was doomed from the moment it was done. Having to redo poor quality work is frustrating. Consider the next person who has to deal with it, instead of rushing through the job.

Just a simple, cost-effective method. Nothing more. No need to stress about a weak connection with wire nuts. If you’re skilled, wire nuts work fine. Crimps are just a convenient option for those who prefer efficiency over everything. There really isn’t a strong case for using them. It’s common knowledge that they’re not reliable.

You’ll find it amusing when you spend 3 hours searching for an available ground

Search it up trunk boy

That’s never gonna happen. Hasn’t in the past 20 years. Hack.

Junkkkkkkkkkkkkk

“Love is love”

….. are you suggesting something questionable?

Not a fan of inspections, huh?

20 years and counting, right? 👌

Failing them isn’t the best idea.

You’re being quite foolish.

I prefer using a green wire nut and leaving one ground a bit longer. I find those crimps useful only in tight boxes where every inch matters, like with bulky switches. They’re great for saving space. I just dislike when the ground wires are cut too short.

I’d rather not deal with those. Most people avoid them. They’re a pain for service work. It also varies depending on your employer. Some companies (usually the cheaper ones) require their use. However, every reputable company I’ve worked for doesn’t use them at all.

When I started out we used green wire nuts, but I was always told to make sure not to trim the wires too short. Leave them with at least one fold.

I’m still sticking with greenies haha, haven’t come across anything better yet.

In order to conserve space, that’s why they’re secured tightly with a pigtail.

But it’s a 3-1/2” deep box with only one device in it. Do we really need to save space?

Just to maintain consistency

This goes against NEC regulations, so…

When did this happen? I see it everywhere I go.

I’m not exactly sure about 300.14, what year was that?

I prefer using greenies for the grounds, the inspectors always want to see them around here but personally, I like splicing the ground together and tailing off, especially in switch boxes. It bothers me when they leave one long ground

I see your point and I’m guilty of using them, but I still prefer to use deep metal boxes for old work with Madison bars.. haha

Are you in a residential area?

Yes indeed

Why do you live there, ? Is that the area code for your location?

I personally use wire nuts and make sure to leave 6″ of conductor, unless the box is deeper than 3 1/2 inches, in which case 3″ is sufficient. I leave enough conductor for the next person as required by the code.

If you let them sit for a while with some of the wire untwisted at the entry point of the box, it makes it much easier to separate the crimped wires later on. This also applies to wire nuts, especially when using automatic spinners.

Hey Ryan, you really opened my eyes to something. I now understand why many guys prefer 18 cubic inch boxes over 14 cubic inch boxes. It allows for more space and depth for the 6-inch connectors. I did some calculations on the potential extra cost of using more copper compared to the price variation in boxes. It definitely makes sense for the larger setups.

I prefer to have one ground wire extending at least 6 inches past the box opening, even though technically 3 inches is enough. It just makes it easier to fit all the wires in neatly.

Hey Armando! For NEC compliance, all box wires should be either 6 inches from the entrance or 3 inches past the face of the box. Unfortunately, this installation does not meet those guidelines.

I always place them about six inches from the front of the box, then extend them three inches past. ood luck with your connections, and if you ever need to replace it in the future 😳🙄.

NEC 300.14 requires wires to be at least 6 inches from where they enter the box. It’s always good to have more space if possible, but keep in mind that larger devices like USB receptacles, FCIs, or dimmers might need more room.

Hey, we should update the code because it’s not good. Over time, switches, plugs, and wires will need to be replaced, and the wire will get shorter. Can you imagine? 😳🙄

Yeah, that used to be the norm. However, nowadays, clutter isn’t much of an issue with the modern deep boxes that are around 3-1/2 inches. Personally, I prefer having sufficient wire length on all ends, just in case any future work is needed.

Most of the time, you’ll likely need to pigtail for receptacles since they’re usually jumpered through the boxes.

I totally agree. Over time, outlets and switches tend to be replaced, and sometimes wires end up breaking during those changes, requiring redoing them. 🙄

If it’s just two wires coming in and two going out, you can simply wrap them around the screws on the outlets, tighten them, and you’re good to go. No need for all that cutting.

Oh yeah, that’s probably only about a quarter of them. I’d suggest leaving longer wires if there’s just one set in the box! 😂

You know, when it comes to electrical work, I try not to overload my boxes. Typically, I only deal with two sets of wires – one coming in and one going out on outlets.

If you have 2 sets, then you should pigtail and your argument becomes irrelevant. Just replace the pigtail if it gets too short.

I already mentioned to wrap them around the screws and you’re good to go. On the ground, you can use a crimp sleeve and that’s it. It seems like you haven’t been doing electrical work for very long, unlike me, with 40 years of experience as a licensed contractor in California, trained by the best

I can’t believe you use the *device* as the connection instead of properly pigtailing, and you’ve been doing that for 40 years? 😭

Wrap around the screw instead of behind the outlet hole, do you realize how much time you waste pigtailing everything compared to just wrapping around the screw 😳

I think you might benefit from some retraining as you seem to be wasting time and wire nuts, not very cost-effective 🙄🤣🤣

That sounds terrible. 🙁 I hope you can retire soon

I hope your boss doesn’t end up broke with the way you work! 😂😂

Have a great day, rookie! 😄

I think the US code still allows it for residential areas. In Canada, pigtails have been required since 2012.

A waygo would definitely be a quick fix for this, especially just for a ground wire.

I hear you, but it’s still not up to code.

Hey, just a heads up, using an outlet as a pass through/junction is not recommended.

I’ve been working in commercial electrical for almost 20 years and using the device as the junction hasn’t been allowed by code in Canada for commercial that entire time and for residential for over 12 years. I guess the US is just behind on yet another fire hazard with their code revisions.

🤨 would you do the same in a plastic box???🤨

This is exactly where I like to use them.

So you’re daisy chaining every outlet. Instead of pigtailing and allowing it to be a parallel circuit, you’re wiring everything in series so when one outlet goes out, everything downstream goes out too.

I would much rather pigtail

How about changing out that solid bare for some insulated ground? That’s the only thing that bothers me about residential – the bare ground on the devices.

It is what it is. There’s never an insulated ground using NM.

In the past, they used to include an insulated ground in some of the romex. I have observed it in some older residences.

What are you on about no parallel wiring we’re not connecting Christmas lights 😳🙄🤣🤣

The sole way that could occur is if someone damages an entire outlet that will disrupt the circuit otherwise that will occur in years 😳🙄🤣

Josh I have no idea what you find amusing but it seems you’ve never encountered romex with an insulated ground.

Not in the slightest. You believe outlets never malfunction on their own?

How frequently do you reckon individuals switch devices?🤣

I’ve had experience working in high-end places like Beverly Hills and Bel Air. It’s interesting to see the different styles and colors that change every few years, from regular to decorative including switches. Pretty cool, right?

What’s the issue with having bare ground?

40 years? I highly doubt that. I’ve been in the trade for 9 years and I can tell this is not up to standard. ood luck fixing all your previous work.

Hey, I’m actually a licensed contractor in California since 1992. Just wanted to clear that up.

You seem to have been struggling with your work since 1992. It’s good to be aware of that lol.

Hey, no need to be rude. Can you please go grab the wire stretcher? 🤣🤣🤣

Not exactly, check out the exception at the end of the rule. If there are ground screws in the box, only the one connected to the outlet or switch needs to be 6” long

That approach wouldn’t be accepted in Canada. For an in and out circuit, pigtails are necessary to prevent interruptions to other outlets on the circuit

Ryan erald in commercial settings, we only use pigtails to avoid disrupting business activities. But in residential work, it’s fine to do it that way

Ryan erald the exception is specifically for conduit and wires passing through the JB without splicing. When 2 ground wires are spliced together, that’s considered a junction

I heard you guys have different plastic boxes down there. Ours come with two ground screws. You can run 4 separate lumex’s into it without splicing the grounds

Hey, make sure all the ground wires stick out at least 3” from the box to meet code requirements

I like to keep the wires about 6 inches away from the box’s face because it helps with connecting and rolling them in once the other wires are attached.

I hear what you’re saying – so basically, when you have 3 wires and you crimp them 3″ outside the box, one of them ends up being around 6″ to connect to the receptacle while the other two are just 3″. You don’t measure them exactly, you just estimate 3″ which might be slightly more.

That sounds great, I like to crimp my grounds right at the front of the box so they are barely crimped and leave about three or four inches out from the front.

I always make sure to keep my hots and neutrals 3 inches from the face when wiring in outlets. I leave them 6 inches from the face of the box for easy access later on since outlets tend to get changed over the years. Thinking ahead for the next person who might need to replace them, whether it’s in a few years or even 10 or 15 years down the line.

It’s best to troubleshoot circuits while they are still hot, otherwise you risk running into potential dangers. Trust me, .

Sure thing, ! You can actually do that. The outlets are rated for pass-through as long as there is only one wire per screw.

Yeah I know, unfortunately lol. I think it should be standard practice for them to be pigtailed so as not to disrupt the rest of the circuit when replacing a receptacle or when one malfunctions 🤷🏼♂️

Brooks Most failures occur with backstabbed devices under a heavy neutral load

Yeah, lots of people are backstabbing and it’s pretty disgusting haha

Yeah

Doing things by running the load from an entire circuit through each device as you go is not the best approach. If you consider a couple of extra minutes and a couple of wire nuts a waste of time, I kinda hope you’re retired by now.

Hower let me share something with you I was a contractor since 1992 I did many many jobs never had one call back so there you go 😀

Hower the evidence is in my quality work I don’t do shoddy work maybe you do maybe other people do I don’t get call backs 🤣

That’s fantastic. It’s still not a good idea to run the full load of any given circuit through each individual device. You are definitely entitled to your opinion, have a wonderful day.

Hower in the US and California you can do it that way for residential you wrap it around the screw there’s a solid piece of metal that connects the two. I don’t do that in commercial commercial I always pigtail because it’s a business they can’t be interrupted by me shutting the power off and all that have a good day

I never mentioned it couldn’t be accomplished I just think it’s not a good idea.

Hower well that’s okay that’s your perspective but I prefer saving on the labor and all those wire nuts and time to do all that it’s residential it’s not commercial it’s not industrial you won’t have a call back

I think it’s wonderful that you do whatever works for you. Complaining about such a tiny percentage of the total installation cost just doesn’t add up to me. And even if you claim not to have callbacks now, eventually, you will encounter burnt-up receptacles on your installations. And when that happens, you’ll end up losing the entire circuit, not just the problematic receptacle. If you’re willing to cut corners and work that way, it’s entirely up to you.

Also, if you’ve ever run a receptacle circuit as a multi wire branch circuit and had the conductors passing current through the receptacle, that’s a violation of the code.

Hower If you get yourself a large number of track homes – let’s say 100 units or even a thousand units – as a contractor like myself, you understand the cost-effectiveness of doing things my way. Just accept it – you do it your way, and I’ll do it mine.

Absolutely, money over quality, right?

Hower Oh yeah, if I don’t prioritize quality, why haven’t I received any callbacks? 🤣🤣

O ahead and do whatever brings you joy. It’s unlikely that you’ll find many people who share your perspective.

Hower, you know what I’ve learned over the years? It’s essential to not give a s*** about what anyone else thinks 😳🙄🤣🤣

😂, my friend, you still have a lot to learn!

Over the years, I’ve found that people who make that claim usually aren’t the greatest folks around. You’ve made it pretty clear that you prioritize money over quality, and I understand.

Well let me just say, boy, I was in Baghdad before you were even in your Dad’s bag 😳🤣🤣, which means I’ve been doing electrical work before you were born. You really don’t know much at all 😂

Hower, it seems like I must be living in your head because you just can’t seem to get over it, can you? Maybe you should consider therapy, but first, let’s have a beer and relax. Stop trying to get to me, none of you will be able to get under my skin 😳🤣🤣

🤡 hey, remember to stick to your 3-inch rule! Oh, and by the way, your mom likes my bag!

You’re so clueless you don’t even know what you’re talking about, you probably never worked a day in your life in electrical work, buzz off

You should have stayed in your country !

o back and pull some 3” wires

I just clicked on your profile to see if you look as silly as you sound 😂😂

Buddy let’s compare bank accounts !

o back to baggerdad

Definitely 😂😂😂

Buddy let’s check bank accounts !

Return to baggerdad

Hey , you sound ridiculous. You probably support Trump. Before I block you, I just want to say, go away! 🤣🤣

I’m just messing around with someone who is adamant about not caring, but here they are. It doesn’t matter to me what kind of work you do.

If you were indifferent, you wouldn’t be putting in so much effort to argue your stance.

Hower, you just keep going and going. I’m just playing along, but I am definitely better at it, especially when it comes to electrical work. Okay, I’m officially done with you now. I’ll just remove you from my comments. 😂😂

If anyone replies to my comment with something silly, I’m just going to block them and move on with my day! 😂😂

So, if Ryan erald didn’t follow those rules, then they would basically be fired, right? So, that still wouldn’t count as an exception. Like mentioned, the exception is for wiring that is continuous, unspliced, and not terminated through a junction box.

What are your thoughts on push-in wire connectors? My inspector gives them the green light, on the condition that they are only used for grounding wires between 12-20 gauge. No other applications.

Wago connector your inspector is a wise man, indeed. While I would agree, personally I prefer wire nuts and twisted wires 😀

Twisted wires and nuts are my go-to as well. However, in the photo provided by OP, there’s less than an inch of wire sticking out of the box. To fix this and extend it, using a push-in connector would be ideal. Once the installation is complete, it would be protected. It’s definitely better than having to run another line of romex due to a short wire.

I recently made the switch to lever Wagos and the new leviton lever-connect receptacles. I used to be against them until I learned more about the design and the differences between those and a cheap push-in receptacle.

Electricians are usually pretty wary of things they aren’t familiar with or that resemble something they had issues with in the past, and I’m no different. But considering where the rest of the world is going, it seems like we’re moving towards more push-in and lever connections and less wire nuts and crimps.

Anything Leviton is good with me.

Nah

Lever wagos rank higher than push-in connectors, but fall below twisted wires, wire nuts, and screw terminals.

I always make it clear to my team: leave a foot of wire or you’re out. That’s one of the first things I tell them.

I recently saw a post from someone in Europe talking about how they’re planning to make insulated ground a code requirement over there. Exciting stuff! 💁🏻♂️

Armando, dude, maybe just stick to handyman jobs if you’re not familiar with the basic NEC code.

Hey there, I’ve been an electrician longer than you’ve been around, kid. I’m a licensed contractor, so stop trolling and move along. 😳🙄🤣🤣

And by the way, screw you and the horse you rode in on! 😳🙄🤣🤣

Just and only the new text: and by the way, screw you and the horse you rode in on! 😳🙄🤣🤣

That’s why you should leave it long enough to start with

Ouch you really know how to hurt people’s feelings huh… ? Oh wait I think I hurt yours huh…! Lol all you had was a generic curse saying to try to insult me bro… 😅! You’re a fool..! Lol

You’re the only fool, you don’t show your face because I’m sure your profile looks as silly as you sound 😳🤣🤣

Get out of here with that trolling nonsense push it

Those crimps are a pain for the next person who needs to come back and work on the box. I’ve been in the field for over 20 years and I’ve rarely used them outside of trade school.

Gave his consent.

I’ve gotten pretty skilled at taking them off. I can usually wiggle them loose just right so they come off easily. And if it makes sense, I’ll reuse them again.

Join the industry. ain at least 4 years of experience and then reconsider this question 🤦

https://t.me/+3PuHpweBWCI0OTY0

I’m not pretending to have all the answers, but I’m currently preparing for my Oregon supervisor and inspector exams, so I’m likely spending more time poring over a code book than most.

Instead of criticizing, why not just respond to the question?

Nope . Put in the effort and figure it out like any other skilled tradesman. Come wear a tool belt and work alongside me, and I’d be more than happy to show you the ropes.

That’s what I’ve been doing for the past 8 years, and nobody who does it like this has a good explanation except that the boss trained them that way.

It doesn’t matter if you’ve been doing something for 1 year or 50, it’s never too late to pick up a new skill.

😊. Who claimed I’m not learning? I’m learning every single day. If you’re not learning, you’re stagnant.

I feel like people are really focusing on the crimps in this discussion, but the main issue here is the super short conductors. No matter which splicing method you choose, make sure your wires are at least 6 inches from the sheathing or extend 3 inches past the front of the box – whichever is longer. I’ve encountered this problem before and it’s frustrating to work on a box that’s wired this way, especially when you have to reconnect those extremely short grounds.

Yeah, you really hit the nail on the head. I actually brought this up on reddit a few days back and got slammed by a bunch of angry resi guys who thought I was bashing everyone who uses ground crimps, so I made it super clear that wasn’t the case.

I can’t stand ground crimps… use green wire nuts. Also, all grounds should extend 3 inches past the outside edge of the box, one of them 6 inches out from the edge, twisted, crimped, green wire nut, wire nut with a pigtail, lever Wago… whatever you prefer to use. Then push it to the back of the box. That’s how I do it and it’s code compliant

We typically leave 4 inches of wire outside the box. If you tuck it in properly, it should be fine.

You just require a SINLE ground wire to exceed 2” in length (minimum of 6” for it), however the others ought to terminate at the rear of the box.

Ryan, why is there only one? Can you show me where it says that in the code?

Sorry, Ryan. You need to read the code.

Hey Wiley and Mike! Just a heads up, only one of your grounds should connect to the device, while the others should be attached to the box (or at the back of the box). I’m guessing you’re both following NEC, not CEC.

Make sure to leave at least 6 inches of free conductor at outlets, junctions, and switches for splices or connecting devices. If the opening is less than 8 inches, each conductor should extend at least 3 inches outside the opening. And remember, if the conductors are not spliced or terminated, they don’t have to follow this rule.

Hey , did you double-check that sentence before hitting send? It’s like I mentioned before, bare conductors that only need to reach the screws at the back of the box don’t have to follow the 6” rule. Just remember, in a single gang box, only one bare conductor needs to be 6” long. The others can be as short as you need them to be, as long as they reach the ground screws.

Make sure the cable is at least 3 inches long, unless you are terminating it directly into the receptacle – in that case, it needs to be 3 inches long. Keep in mind that a pass through or splice is the only exception.

‘s exception only applies if the wire is not being connected or cut off at the outlet or switch. If the wire is only going to the screws in the back of the box, it means it is not reaching the outlet or switch.

So basically, Ryan, if the conductor is being used in that device, it’s considered the exception. This means that if the circuit is not being used in the device.

Hey Ryan, just to clarify, the box is labeled as an outlet, not a receptacle. The wire is being terminated in the outlet.

Remember, only one ground wire counts towards box fill 😂

I’ve dealt with houses that have wiring like that before, and it’s always a hassle. That’s why when I use those crimps, I make sure to leave the ground wires long enough so that the next person working on it can easily cut behind the crimp and have plenty of wire to work with.

People who cut corners and shoddy electricians are the ones who do this.

A bare ground wire is something you don’t want floating around. It looks like that one would lay back nicely.

Whenever I needed to swap out the box, I made sure to keep all the wires long with a green wire nut and a deep box.

This is how it’s done.

I miss those green wire nuts

There is limited space in the box.

5 turns, remove the bad buddy, tough turn, Buchanan.

No content

This is exactly why I avoid leaving loops, regardless of personal preferences.

I get your point, but at least there are ground wires in the box half the time when I arrive I don’t see anything not connected together or on the device

Hey there, , remember to appreciate the good things in life!

I come across this situation all the time. I always advise the guys to make the connection, push it into the back of the box before trimming the wires. Make sure to leave at least 6 inches of wire on everything. If any joint needs to be removed to connect the device, then it was done incorrectly. It’s more difficult and time-consuming to fight it back into the box while trying to put the device in. It’s really challenging to change old habits with some guys.

I still remember the time we crimped every box during a rough home installation back in 1998. Our boss instructed us to crimp like the picture showed. The inspector ended up failing the entire rough-in because the wires were not crimped at least 6 inches long. We had to raise every box in the 6,000 square foot house – it was a total nightmare.

I totally agree, I can’t stand working with wires that are too short. I’ve witnessed situations where only the hot and neutral wires are barely an inch out of the box from the old timers. It seems like they wired the plugs first and then pulled the wire as tightly as possible to connect the next one. What harm is there in having an extra 30 feet of wire for the entire job? It’s really difficult to fold two twisted grounds in the box

Do you need anything else? ood connection

That’s something only foolish people would do.

Use green or a wire nut of some sort. Just hack if you’re going to crimp

Come on, just solve the issue and stop whining, do I have to come pull you out of the hole.

If you just follow orders all day and remain a journeyman until retirement or death, that’s not my game plan.

Maybe not the best way to go about it, but definitely not a code violation.

That’s my approach as well.

That was a ridiculous mistake. I accidentally cut myself on a sharp Buchanan short corner. It’s so silly, but we’re fixing it now 😂

There are many different types of coffee available for purchase.

There are so many different kinds of coffee to choose from.

No content

Can’t stand those!

That’s not new construction…… I haven’t seen orange peel in at least 15 years

Hey, check out this brand new 22 unit apartment building geared towards “affordable housing”

Wow……. and since it’s government-funded, they don’t prioritize code….. noted

– You must be mistaken if you believe they don’t take code seriously. THAT’s how they earn their bonuses.

Christopher the inspectors on government projects are a joke and you must be crazy if you think they care

– You’d be surprised how many of them are just in it for the cushy job… I work with people who DESPISE the government, but absolutely LOVE their paychecks. 😂🤣 Hearing them speak in the conference rooms could be considered fraud.

Christopher that’s what I meant. Super cushy (serious pay cut too) and no Fs to familiarize oneself with or be thorough

– PS – Deciphering sarcasm through text can be quite challenging.

Some folks are perfectly content with not having a ton of money. And if you dedicate enough time, your salary could double, your retirement savings could increase, and your job might become a breeze.

They seriously need to create a font specifically for sarcasm, Christopher.

I would use it all the time 😂🤣

Hey Christopher, over the past few years I’ve been approached about switching to the dark side about 5 times. If I were to make the move, I’d be looking at a pay cut of around 60 to 70k a year to work in inspection.

Your comment about improvement over time doesn’t really hold up, especially with the introduction of pay equity in certain areas.

– As the older employees retire, many companies prefer to promote from within.

Christopher once again… equity pay is based on equality. There’s no preferential treatment based on seniority, so everyone receives the same pay rate.

– Sorry for the confusion earlier. I was talking about advancing in the hierarchy. Pay grades remain fixed. Equity pay is strictly based on equivalent grades.

Christopher… as I mentioned before… whether you’re an inspector or an electrician, the pay is the same according to equity standards. So there’s no opportunity to move up within the inspector role with my level of experience.

– The top earner here makes $202k.

Christopher is either an inspector or an electrician.

– I can’t remember his exact job title, but he’s the one in charge and decides whether to approve or deny variances.

Hey Christopher, what’s your take on the CBO?

Hey , what kind of texture do you think everyone’s house has? It seems like orange peel to me.

Hey Chance, looks like it’s all knockdown around here.

Make sure to check the proof before making any payments! Prices range from R150 for 800 units to R450 for 2000 units. If you’re interested, feel free to send me a message.

Try pinching the crimp in the opposite direction to open it instead of cutting it off, that way you won’t lose any length. Crimps are designed to be used this way to maintain the full length.

I would guess it’s either a code violation or someone being rude on the job site.

Come on over and be a part of Blue Hedge Market Solution! We’re all about guiding people towards financial freedom and early retirement. Our group promotes saving and investing smartly, building up various income streams, and securing a stable financial future for everyone.

I was always taught to leave a gap of 3 fingers from the box

This can be quite irritating, so please refrain from doing it.

Hey everyone, send me a message with your business name if you want a cool and original logo design! I’m in a creative mood and ready to get started.

Following 300.14, if the box is 3.5 inches deep, the conductors should be a minimum of 6.5 inches long. You need at least 6″ and 3″ past the box opening to comply.

For a single gang box, only one bare conductor needs to be attached. The others just need to be long enough to reach the ground screws. (Doesn’t apply to the box in the picture without ground strap/screws)

Hey Ryan, can you give me the code reference for that statement?

Does Ryan erald’s question only pertain to a single grounded conductor and a single ungrounded conductor?

Trash

I can’t stand those things. I always opt for a green pass-thru wirenut… much better in my opinion.

This doesn’t make any sense! Make sure there’s enough wire to work with!

I’ve encountered this issue too, and they’ve installed a ground crimp fitting. If I have to replace the box for any reason, all but one wire is either too long or too short. It makes reconnection difficult and non-compliant with the code.