What is the most effective method for securing the pieces of a pull up bar during construction?

9 months ago

Last Updated: September 17, 2024

I’m in the process of putting together a pull up bar. Do you have any tips on how to best secure these pieces together? Thanks a bunch!

Carriage bolt or lag, right?

Tool for creating pocket holes

‘s second home pocket jig

Chewable product used for freshening breath

High-quality fasteners known as GRX

Secure everything in place with a finish nailer.

Cut a piece of plywood into two triangles to match.

Attach both sides with glue and screws.

Using a Kreg jig to hide screws.

Hardware

Personally, I wouldn’t feel comfortable relying on pocket hole screws to support my full body weight while doing pull-ups.

I would secure them in the ground using cement.

For securing pieces together, consider using glue and dowels. If you need to create a hole for pilot screws, you can use a cap or plug to cover it up.

Personally, I recommend using metal nailing plates along with screws.

No content

How will it support a pull-up bar? In what orientation? Which direction? What components are involved? What is the bar specifically mounted onto or into?

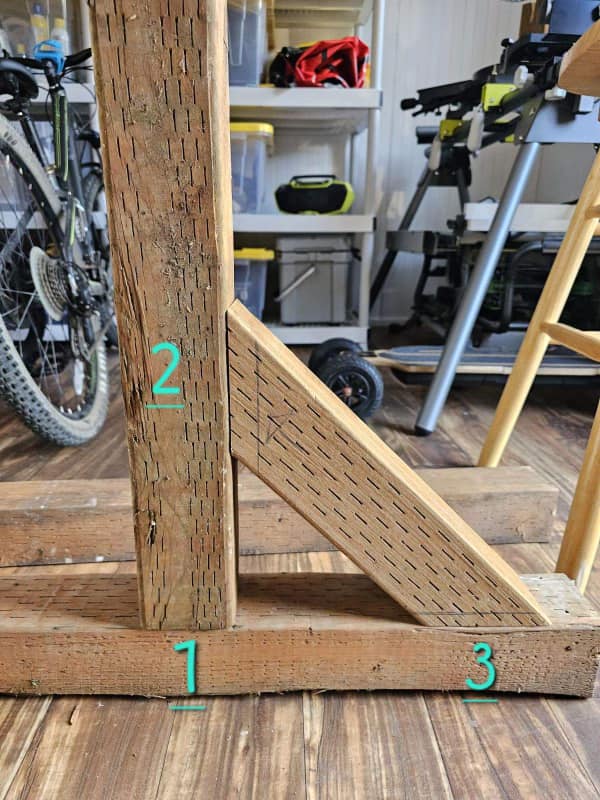

You can either use metal straps or opt for through bolting 2&3 while securing them with a couple of sturdy lag bolts (pre-drilled) on 1. If you choose the metal T straps and through bolt them, you should be good to go.

Secure it in place using long drywall screws and then attach lag bolts from the bottom and side.

I recommend using carriage bolts and nuts along with washers. This way, you can easily adjust the tightness without risking stripping when the wood expands or when your weight causes the miter cuts to loosen. Make sure to have a long 1/2-3/4 drill bit for the bolt diameter and a spade bit for the washer diameter. Use the spade bit to create counterbore holes in the 45-degree brace for horizontal washer placement.

Consider using plywood gusset plates or dominos.

I’m seeing some hilarious responses here. Personally, I think lag bolts would be the way to go.

It’s annoying when it gets old, but I just block the ones who are desperate for attention.

Has a good idea, doesn’t she?

Bolts. Pre-drill the holes for easy installation

Depends on how strong you want it and the weight of the people using it. Wood has the potential to split, so what I would do is route out a notch that is one inch deep for the main leg to fit snugly into the base. Then, secure it in place by gluing it with wood glue and using lag bolts from underneath. Make sure to use a paddle bit that is slightly larger than the socket required for the lag bolt, and drill to a depth of about half an inch to ensure the bolt is properly recessed into the wood. Afterwards, continue drilling with a 1/4 inch bit and fasten with 3/8 inch by 3 inch lag bolts.

Flex tape

If it were me, I’d strengthen those two right angles with some sturdy iron corner braces and bolt them through the wood.

No content

I would also recommend adding support on the opposite side

Best option? Mortise and tenon.

Better choice? Bolts with large washers and nuts

Good option? Timber locks

Placing a piece of plywood over all joints and screwing and gluing it down will significantly reinforce the entire structure

Oh, a pullup bar. I was all set to go to the bar and get myself a bourbon.

Right?

Joinery is not an option after cutting the pieces. It’s difficult without the proper tools and experience. Keep it simple but sturdy. Imagine an old steel bridge. Cut a triangle from 3/4” plywood that covers all three faces of the 2×4. Trim the sharp 45 degree corners and sand down all exposed edges. Attach it to the main structure with glue and screws. I used Liquid Nails and tan deck screws of the correct length. Pilot and shank holes aren’t really necessary. Apply glue about 1 inch in on the 2x4s. If it seeps out, that’s actually a good thing structurally. Time the gluing process so that in 4-6 hours, you can return with a utility knife to trim off the excess rubbery glue. ‘t wait too long or the glue will be difficult to cut. Following suggestions, I recommend adding another 45 degree 2×4 brace at the back. The plywood stiffening plate will then resemble a simple airplane, like the blue arrow. The screws act as clamps for the glue, with the strength coming from the glue itself. Avoid using fasteners (bolts) that protrude. You don’t need a lot of screws, just enough to secure the heads slightly below the plywood surface. You can attach the airplane plates on both sides of the uprights, requiring a total of 4 plates. In this scenario, 1/2” thick plywood will suffice. Smooth out all edges to prevent splinters. If your 2×4 framing is AC2 exterior treated, consult your store for the appropriate adhesive. Best of luck constructing the rig and body.

Whoops, I overlooked that you’re using 4x4s. 3/4” thick outside plates should be strong enough. So keep it simple, just use glue and screws. Make sure to use the right Liquid Nails or Loctite adhesive, and have a caulking gun handy. Polyurethane adhesives may be stronger, but they can get messy. For screws, LedgerLOK Flat Head screws are recommended. Place paper over the Upright/Angle intersection and rub the edges with a crayon. Then, carefully plan the screw location and length with a pencil. Make sure the screws are perpendicular to the 45-degree brace face and enter the uprights at a 45-degree angle. Be mindful not to place the screws too close to the top edge of the brace. If adding braces to the back, offset the screws carefully to avoid crashing into each other. The glue oozing will be the same as before. This method is simple, strong

Can you please take a look at my other, more straightforward idea?

If you’re referring to hardware, use the included screws. Replace 2 with 1, 3 with 2, and 3 with 1.

Avoid screwing into the end grain, it’s not as strong as screwing into the sides

Use truss-loc lags and you’re good to go. It doesn’t have to be perfect, right?

Consider using framing screws – they are quite DIY-friendly for a project like this and provide enough strength for a deck. You could also incorporate straps/plates for added security if you prefer.