Is there anyone experienced with step-up transformers who can offer advice on adjusting voltage levels for a laser with a primary voltage of 245-246v?

9 months ago

Last Updated: September 11, 2024

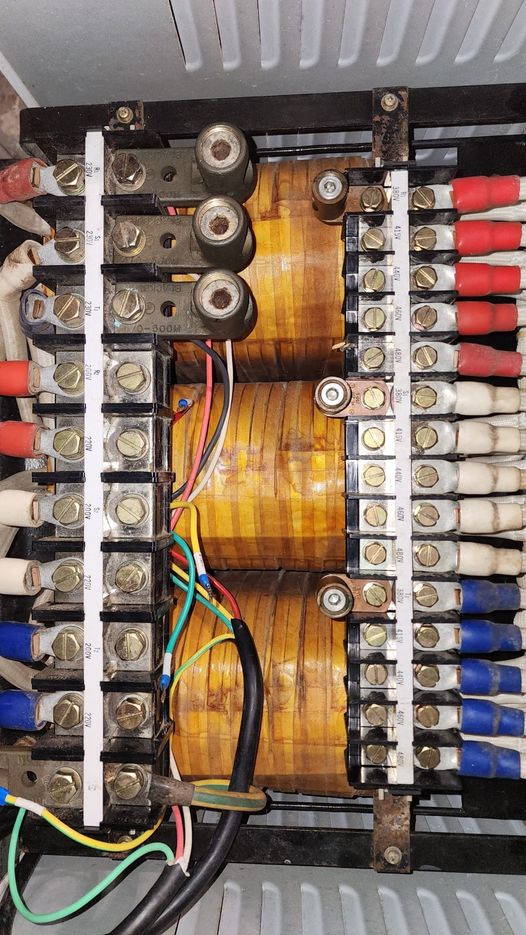

Does anyone here know a bit about step-up transformers and could give me some advice on how to adjust the voltage on the secondary side? My laser requires 380v ±20 with a max of 16a. My line voltage used to be 228-232v, but the electric company recently upgraded and now it’s 245-246v, causing the secondary voltage to be 414v which is too high for the laser. Any suggestions on how to reconfigure the wiring on the transformer to get it within the 380v range, or any tips on how to lower it back down? Thanks in advance for any help!

Are you using a split phase supply or a full 3 phase supply? As a UK electrician, I thought the US typically used 120/208 and 277/480 as the primary supply voltages for 3 phase systems. Your readings of 245 lead me to believe you only have a split phase 120/240 supply.

Is at 240 delta

Ah, high leg delta, I’ve heard of it but it’s not common in the UK on public supplies.

So, that clears things up for me, which means tap settings alone won’t solve the issue with the transformer.

There are a few options you could try. One is to balance the input lines, this won’t change the open circuit voltage on the secondary but will reduce the loaded voltage. Whether that works for the laser and calculating the ballast impedance, I can’t say without more details.

The next option is to use voltage optimisation on the secondary, which are auto transformers with tap changers to keep the output voltage constant regardless of the load, and can adjust by 5-10%.

The third option would involve modifying the transformer windings by removing turns from the secondary, but that’s probably not the best choice, especially if the windings are coated in lacquer.

Might need to turn in the opposite direction a few times

You’re already at the highest input and lowest output with this transformer alone, so it won’t work. You could try adding a buck & boost transformer before this one, with 240 in and 208 out. With your current voltages, you would get around 215 out. Then move your primary taps to the staggered 200 terminals. Unfortunately, it’s going to cost you about $400.

Rex ammon $400 is a super light.

It depends on how many taps are available on the transformer…your options may be limited with that particular transformer.

I agree with Rex gammon, I don’t really see any other options. Basically, you just need to buck your voltage down and move your taps to the 200 terminals

Would you recommend using a buck/boost or autotransformer in this case?

Having an image of the nameplate on the transformer would be really useful.

I was struggling financially until I met my landlord, things turned around when I started with a small investment, I highly recommend Mrs Laura Andreas

I think using buck booster transformers would be a better option than trying to ‘update’ the service to 120/208

I think using a step-down autotransformer to convert to 230v could be beneficial.

You would have a 240v high leg delta primary and a 230v high leg delta secondary.

These buck/boost step-down autotransformers usually start at 30A and then go up to 40, 50, or 60A for machine mounting.

You can find them online for $350 to $1400.

You might be able to get a 100A floor-mounted one for cheaper at around $850.

It’s really difficult to make out the name plate, .

If there are no taps available on the transformer, it might be time for a new one. It’s not recommended to make alternative design modifications as they may not meet the codes.

For single phase situations, consider using a stepped auto-transformer.

That 380 50 htz is = to 480 60 htz