How can I safely disconnect a stubborn water hose from the spigot without damaging the pipe, despite trying wd40 and two wrenches?

11 months ago

Last Updated: July 26, 2024

Hey, anyone have any tips for getting this water hose off the spigot? I’m worried about damaging the pipe. I think it’s just connected to my PEX piping. I’ve tried using WD40 and two wrenches, but it’s not budging.

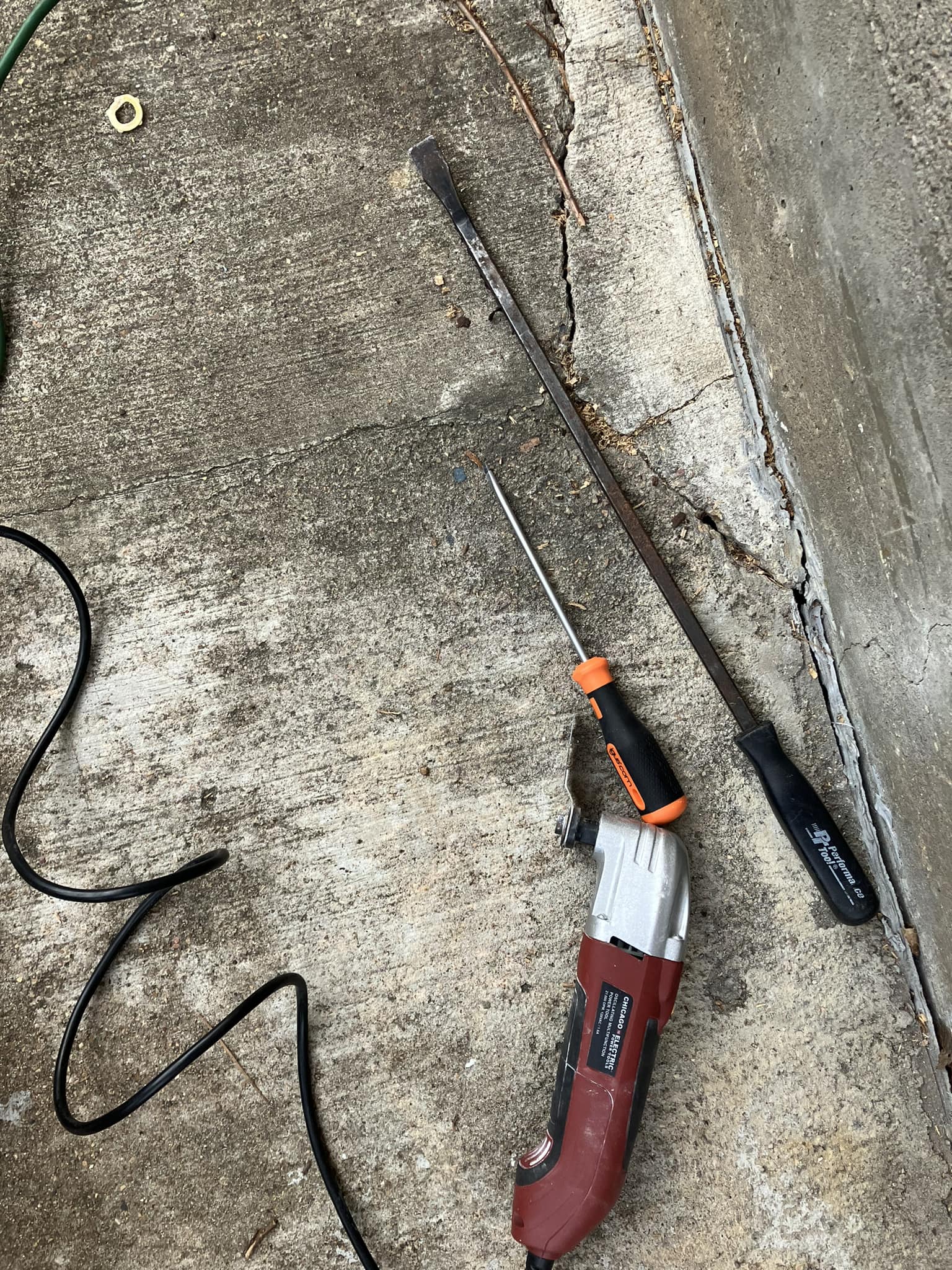

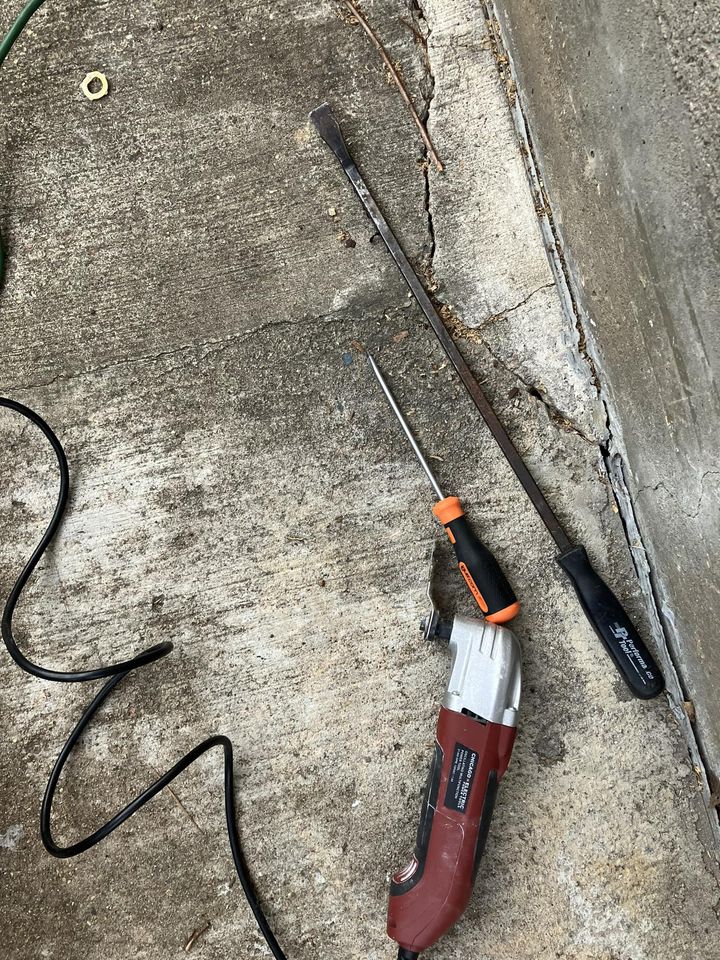

Update: Thanks for all the advice! I ended up cutting it in half and twisting it with a flathead screwdriver. Worked like a charm! I’ve posted some pictures of the finished job below. Thanks again!

Torch

Yeah, I think I’ll need to warm it up a bit.

I’ve tried that in the past, but it’s a gentler approach if you trim the female threads to match the male ones and use a screwdriver to widen them.

Seems to be soldered on

Wondering if I’ll encounter this in the future. I’ve soldered pipes before but always managed to cut the ones I’m replacing. So in this situation, should I use a torch to heat it up and melt the solder to remove it?

Absolutely, you should be able to reverse the process by heating it and twisting it off. Keep the heat on it the entire time, then sand off any excess solder from the pipe.

Give it a shot by turning it on for a day and grab two wrenches

After removing it, switch to a quick connect set for easy hose removal. We’ve been using them for years and they’re great!

Try using some penetrating oil along with a torch

It’s attached with solder

The hose is connected to the spigot, yes, but that’s not the issue. He wants to know how to detach the hose from the spigot. It seems like the hose is stuck to the spigot

Make sure to use a second set of pliers on the valve to avoid snapping the pipe in the wall. In the future, stick to hoses with a brass fitting.

Channel pliers

Initially attempted that, then tried using monkey wrenches. The issue is I’m afraid of bending or, even worse, breaking the pipe in my wall.

Has one hand on the hose and the other on the fitting, not the pipe.

Bingo! Try using one wrench on the fitting and another on the hose coupling. Really give it some effort to get it off. If it ends up breaking, well, it was due for a replacement anyway. Another option could be heating the aluminum connection point with a torch to expand it slightly.

I ended up having to cut it from the opposite side of the wall

Just cut it off from the pipe and replacing it is a very simple job.

Crystal Dawn Stewart are you suggesting replacing the entire spigot? If that’s the case, I’ll consider it as a last resort. I’m more familiar with PVC and galvanized when it comes to spigot replacements.

Simply heat it up and slide it off.

What about a hair dryer? If not hot enough, I’m out of luck with a torch…

Haha , yeah you definitely require a torch

As Fred mentioned, you’ll want a large set of channel lock pliers to secure the valve, and another set for the aluminum hose end. Before proceeding, I recommend soaking the aluminum in blast off overnight or using a similar product. In a worst case scenario, you can use a Dremel with a cutoff wheel to carefully cut into the aluminum vertically, stopping just short of the threads. This should allow the aluminum to separate and peel off when you grip it with the channel locks.

I really like this suggestion, I’ll give it a shot before resorting to replacing the entire thing. I’ve attempted using channel locks, monkey wrenches, everything really. The problem is that it’s so tightly stuck that if I try any harder, it might end up bending the pipe or even breaking it off inside my wall.

I’ve decided to stop purchasing hoses or nozzles with aluminum threads because of the issue with dissimilar metals corrosion. If you frequently need to remove them, applying some lubriplate can help, but it’s best to stick with brass to brass connections. You might want to consider having two people to ensure the pipe doesn’t twist.

Are you attempting to detach the black hose from the spigot? Grab the largest plumber’s wrench you can find and give it a go. ‘t forget, righty tighty, lefty loosey. By the way, you may want to tighten that spigot, it’s quite wobbly against the house.

WD40 is not effective in this case. You’ll need pb blaster or a similar product to tackle corrosion. Since neither of these can rust, the issue is likely a reaction between different materials.

You seem to be turning the wrong part. In order to detach the black hose, make sure to twist the silver part connected to the spigot at the bottom. If you keep turning the spigot, it might break off in the wall and cause a water overflow.

Hey , thanks for the laugh! I was just demonstrating how delicate the pipe is when it goes into the wall, which is why it’s tricky to apply too much pressure on the water hose connection. I was also curious about how they attach that metal piece to the pex, which I’m guessing is just a regular T valve.

If you replaced the original with pex, you should be able to access the other side to inspect the connection. It’s clearly not secure. The valve seems standard, but you need to verify where it connects.

Hold onto the spigot and loosen the hose at the same time.

When there’s pex on the inside, the pipe tends to spin due to improper installation. WD40 won’t be of much help here. It’s best to use pb blaster or petron plus for lubrication. Use channel locks on the fitting to prevent spinning. Tighten before loosening the hose bib to break it loose. If all else fails, consider replacing it with a new spigot that allows for screw attachments.

Probably got cross threaded.

Remove the handle to improve your grip on the faucet body using vise grips, then use channel pliers on the aluminum nut.

The issue here is galvanic corrosion caused by two different metals. This occurs when you connect a hose with an aluminum fitting to a brass spigot. Once it’s on, it’s on for good. You’ll need to replace the spigot now. If the hose is still usable, cut it off and replace it with a plastic or all-brass FHT fitting.

Hey , totally agree. Plastic shut offs are the way to go!

Nope, can’t attach it to the outlet pipe without getting a new faucet, and can’t swap out the female connector on the end of the hose.

Remove the handle from the spiket to make it easier to hold with a pipe wrench and use another pipe wrench on the hose

Heat it up first and grab two pairs of vice grips

You know, I was thinking the same thing – definitely gotta heat it up first!

Try using PB blaster

The hose is fused to the bib due to galvanization between two different metals, so it won’t come off in one piece. If you need to remove it immediately, consider using a Dremel or grinder to cut a small slot in the hose collar near the bib. Then, use a large flat blade screwdriver to try and spread it apart. Just be careful not to go too deep and cause leaking in the future.

Really should have a vacuum breaker on that type of hose bib anyway. Just grab a vacuum breaker attachment for the spigot – it’s a win-win situation! Lol.

Yeah, I get code, but I usually avoid it because it’s often excessive and wastes water in many cases. Plus, most vacuum breakers are brass, so the hose would end up getting stuck to it regardless. And even if it’s installed to code with the screw torqued down and sheared off, it wouldn’t necessarily put you in a much better position.

Wouldn’t it be easier to just attach a brass or plastic connector to the end of the hose rather than using a plastic shut-off valve that’s likely to fail within a year or two? Those plastic shut-offs have a small inner diameter that limits flow.

I’m talking about some plastic ones. Not the brass or metal ones

I’m not entirely convinced about that.

In general, galvanic corrosion affects both ferrous and non-ferrous metals in contact. I don’t believe brass is ferrous.

I’ve left the same hose in the picture connected to a very similar hose bib from April to around November without any issues

Aluminum and brass will definitely corrode when they come into contact due to galvanic corrosion. This is confirmed by MIL-STD-889 which lists brass and aluminum as incompatible metals for contact. This happens almost every time, with the rate of corrosion depending on the water chemistry. Farms and livestock, often located in rural areas or areas with high TDS in wells, are likely to experience this type of corrosion.

I trust you, I just had a different experience.

Cut it off, attach a copper male threaded adapter by soldering it on, and then install a new hose bib.

A regular hacksaw can be used to remove the hose adapter. I’ve had to do this a few times in my life. Just make sure not to damage the hose bib threads. In the end, you may need pliers to remove the cut edges and pull off the rest.

‘s technique is good, but if you don’t have a dremel, you can use a hacksaw to make the vertical slot. The other steps remain the same. Just be careful not to damage the round face of the bib to avoid leaks, as the water seal is created by the round face of the bib pressed against the washer in the hose. Use a new flexible washer. If you decide to add a secondary valve or a “Y” splitter, make sure to use brass – no white metals. Plastic is okay but may not last as long and is easy to cross thread. Remember, the seal on all of these is created by a hose washer, with the threads simply compressing the washer/fitting joint. Avoid using pipe compound or Teflon tape, and instead, clean the male threads on the hose bib with CLR or vinegar and a toothbrush or small wire brush. ‘t forget to protect your eyes. A bit of plumber’s grease or V

Is that copper pipe? Looks like it’s been sweat on. The threads on the outside are for connecting to galvanized pipe, but it also seems like it can be sweat onto copper. It’s kinda hard to tell, but that’s my take on it.

I used a cut off wheel to split the water hose fitting.

If it’s stuck, try heating it up and using channel locks closest to the house. If that doesn’t work, you can cut it with a pipe cutter and replace it with a new fitting of your choice.

Try applying some mild heat, PB Blaster, and use big wrenches. It’s likely that minerals have jammed the threads. For next time, remember to use silicone grease on the threads. If it’s still stuck, you can try using a Dremel with a cut-off disk.

Just put one hand on the hose bib/silcock and the other on the end of the water hose, then twist it. This way, it will come off without breaking the pipe in the wall. If you want to make it extra solid, you can use a backing plate against the brick.

Head over to the inside wall and cut it there to push the pex out. Mount it flush against the wall, leaving a bit of excess inside. It may look like it’s sweated on with that copper patina.

I’m not sure what you’re finding funny.

Some of these comments are a bit extreme. You can grab a screwdriver to remove the blue wheel, then use two adjustable wrenches – one to hold the faucet in place and the other to counter rotate on the hose. With a little leverage, you should be able to break it free once the wheel is off.