Can anyone help with a plumbing issue involving unconventional copper pipe fittings that won’t separate despite heat?

1 year ago

Last Updated: April 23, 2024

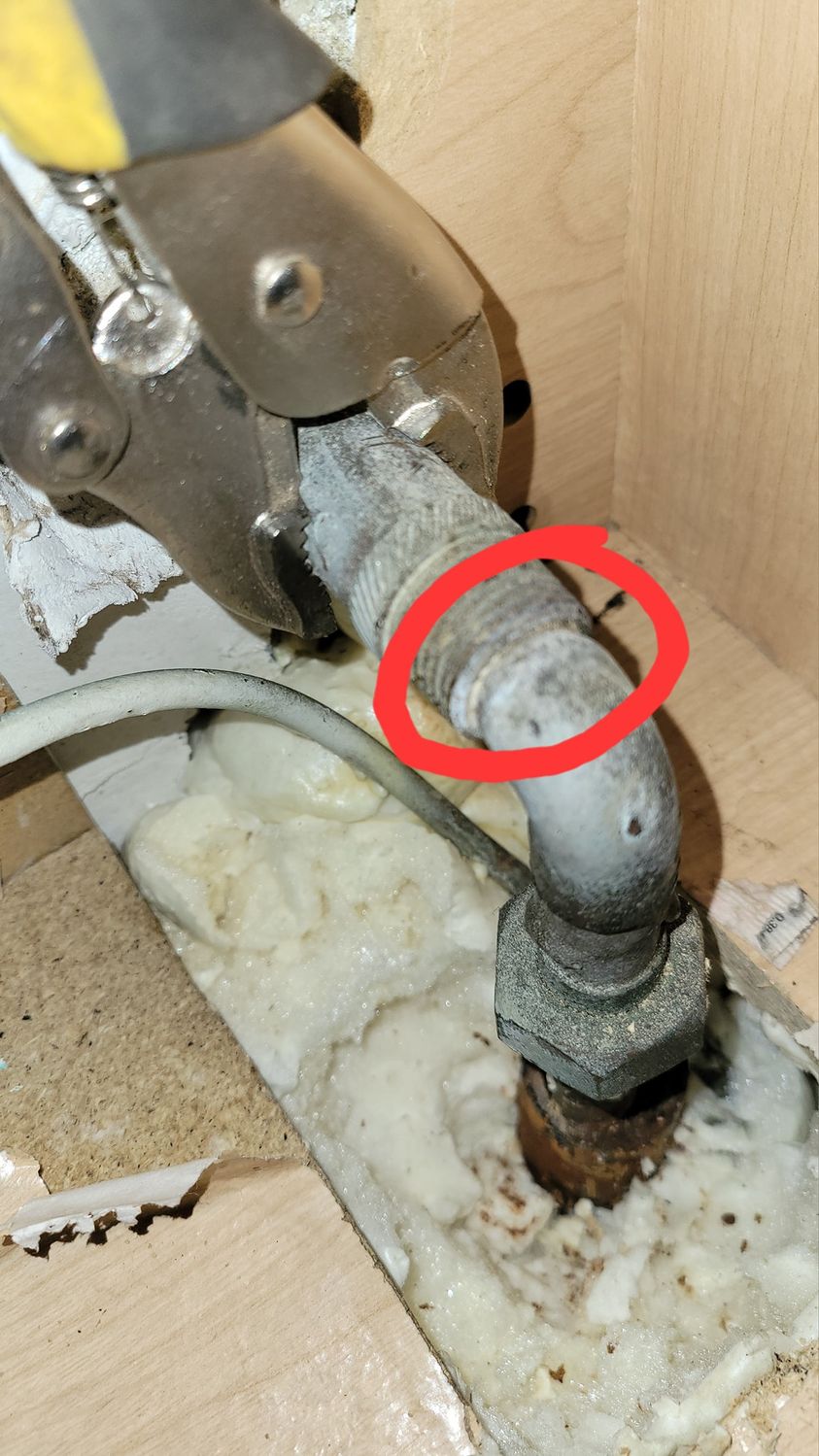

Hey, does anyone know about plumbing? I have a copper pipe connected to an outdoor spigot in a weird way. It looks like someone soldered a smaller piece inside the spigot pipe instead of using a threaded adaptor. But now I can’t get the two pieces apart, no matter how much heat I apply. I’m starting to think it’s not actually solder. Any ideas?

Try using mapp gas instead of propane. I found a situation where they used brazing instead of plumbing solder.

I also considered it could be brazed but I don’t see any indications of it. I believe they utilized epoxy or some form of bonding material

That’s a road fitting entering a female adapter

Mapp isn’t as good as it used to be you’re only seeing a 180 degrees change

Ny Ziegler oh I see. It was fixed years ago. But I wouldn’t recommend a DIY person to get mixed gas and attempt to melt some pipe.

From what I see in the picture, it appears to be a union. If there is water inside, it’s unlikely to come apart.

Removed the contents.

Landon uy took it off at the connection. It’s most likely a dielectric union. It’s not a brand new one, so it should have the same dimensions.

It won’t come apart if there’s water inside.

Is dry

Landon uy, that all seems brazed. You’ll have to use mapp gas to heat it up sufficiently. Your best bet is to rebuild using solder in your situation

It’s been soldered. It’s possible that it was fluxed or cooled rapidly after heating, leading to tempering.

First things first, your vise grips are actually on backwards. Also, you might want to consider using map gas and a pipe wrench for better leverage.

I think this is threaded. You should try using a pipe wrench.

Paul uerrero Smith is present

No, that’s actually soldered. You should disconnect the union and give it another shot, unless you decided to listen to one of these clueless individuals and ended up tearing it apart with a pipe wrench.

‘s union wouldn’t fall apart either. 😂

Landon uy, you should attempt to clean the solder joint with a wire brush and apply some flux before heating it up. Using mapp gas or acetylene is even better if available.

Abriel Rosado attempted but couldn’t get it to budge. It seems like it’s held together with a bonding compound or epoxy.

I’d recommend just cutting it off with a grinder.

Finds himself in a bit of a pickle. Dealing with unions, short timelines, and the unknown lurking beneath the surface. Removing things abruptly could lead to a significant amount of extra work that I am not ready to tackle on my own. Also, there is no dedicated shut off valve. The only way to stop the flow of water is by cutting the main line. If I mess up and can’t cap it properly, water won’t be back on until a professional plumber arrives and charges a hefty fee. Understanding my limitations is crucial. 😆

Landon uy I really dislike dealing with plumbing issues, and as luck would have it I work in maintenance!

Ditto. Particularly when it’s been altered, repaired, and pieced together by multiple individuals throughout the years. They repair something but fail to make it functional

If it’s not getting hot enough, or if there’s water in it, the solder won’t stick properly.

Adding fresh soldier can be helpful in some cases. Make sure to heat it, add flux, and the fresh soldier might come off more easily.

Move the vice grips a bit further from the joint where you’re trying to unsolder to avoid them acting as a heat sink. The whole brass piece your vice grips are on needs to heat up, so be patient. Try moving the vice grips further back from that piece and gently tap the side of the vice grips with a hammer once it’s hot enough to remove the fitting. Remember to focus on heating the brass instead of the copper, as the brass needs more heat to reach the correct temperature and expand for an easier disconnection. Also, make sure to remove the screws outside that are holding the faucet to the outside wall first.

Check if it can be threaded as either male or female by giving it a twist…

Make sure to braise it, braising brass is key

I bet there’s some water inside as well

Yikes! Maybe call a plumber for that one. Probably best to leave it to the professionals

Make sure to loosen this after confirming that the water is turned off. It’s a 1/2″ st90 joint that has been soldered. You’ll need to heat it up and remove the fitting carefully. Heat the brass part, not the copper. Use a bit of solder if necessary to help with the removal. Many hose bibs come with sweat and male threading. There are quite a few trolls commenting on this post…

You can choose to either use a male adapter or solder it with copper on the spigot. Just heat it up until you’re able to remove it.