Are there any recommendations on whether fixing the main beam under our dining/living rooms is a DIY project or should we hire a professional, and if DIY, what are the best steps to take?

11 months ago

Last Updated: July 26, 2024

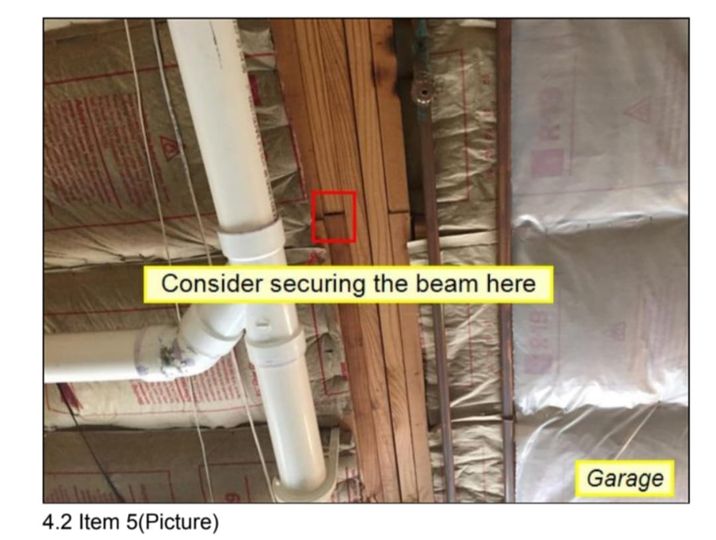

Our garage is located directly under our dining and living rooms, as noted in our inspection report. The main beam that supports the dining, living, and kitchen space runs through there.

Can anyone offer guidance on whether this is something we can tackle ourselves with our DIY skills, or if we should hire a professional? And if we can do it ourselves, any tips on the best approach would be greatly appreciated.

Thanks in advance!

You know, you could totally get a ceiling jack for pretty cheap.

We’ve got those down in our basement. I believe there are 4 of them, each spaced 15 feet apart.

https://amzn.to/49vUSLL

You placed the pins very close to the height. After doing so, you can extend the pad by screwing it in to apply pressure on the main beam.

Probably unnecessary as your inspector may not be a structural engineer, hence the use of the word “consider”. There’s probably a specific nail pattern in place to support the load. To determine if reinforcement is necessary and the extent of it, consulting a structural engineer is recommended.

I understand it’s tough but maybe refrain from answering questions if you’re unsure.

Dietrich, you could have also moved along 🤦

Dietrich, what he mentioned is absolutely correct. If you disagree, feel free to share your engineering degree with me.

Oh, here we go again with another special character who doesn’t seem to know what they’re talking about haha

Dietrich, you seem to be out of touch, arguing with people who actually know what they are talking about. Two structural engineers above seem to agree.

Maybe try using approximately 2 1/2 feet of 1.5 – 3″ angle steel with alternating nail holes and 2″ nails on the sides. The bottom part is optional. This arrangement would help distribute the load more evenly, rather than focusing it all on the two center beams at those joints. Those seams should have been spaced apart for better support. This could potentially reduce any popping or cracking noises from the floor above as the structure settles. If not, the creaking floor might become a problem when sneaking to the fridge at night without waking everyone up. It might be wise to follow his suggestion or do nothing and deal with the floor creak later. Also, consider the length you’re dealing with. If it’s over 8-10 feet, adding a support beam or jack around the middle might be a good idea, especially since it’s not a continuous solid beam. It’s better to be cautious now than regretful later.

It’s hard to make a judgment from the picture alone. I’d suggest getting a structural engineer to assess it if you have concerns.

Edit: I’ll also mention that hiring a structural engineer for this isn’t as daunting as some people think. It usually costs about the same as a home inspection, which could be around $300-900 depending on the house size. I had the seller of my first house hire a structural engineer for a specific detail, and it cost $500 (in Baltimore city). A reasonable price for peace of mind and expert documentation in case of any legal issues 😂

Pop a lolly column and maybe use 1/4 or half inch steel plates around 6×6 or 8×8 assuming the floor can handle it, otherwise you might need to adjust the floor, dig deep enough to pour 12″-18″ concrete, and then install the column. (If this is a basement, the concrete floor should be at least 6″-8″ newer or 3″-4″ if older… unless you’re comfortable with those tasks, in which case I’d suggest consulting a structural engineer

Ricky shared a photo of one, but the smaller steel head plates can be improved by adding larger plates to distribute support more evenly. I recently installed 6 in my house, which was built in 1710 with a concrete floor that was only 3 inches thick. I had to cut the concrete to pour 18 inches of concrete for each column to ensure better footing without damaging the floor.

Haha, oh my goodness…. First things first, is there actually a problem? Is it bouncing up there? Settling? Cracking the walls? You probably don’t need a structural engineer for this. What’s the total span between the LOLLY COLUMNS underneath that beam right now? If you can, please share a picture. You don’t need a vertical post under each joint in a 5 or 6-stack carrying beam. Those commenting might not have the right idea. If you have VERTICAL columns 8′ apart in a 5 or 6-stack, you should have two of them with joints in the same middle spot – making a 4′ CANTILEVER in the middle of 8′, otherwise you’ll end up with a 6′ cantilever on one side and a 2′ on the other. I’m here to provide you with real tradesperson advice.

👆👆 This answer is top-notch 👆👆

Most ‘home inspectors’ typically complete a brief online course and print business cards at Staples. I once had one discourage a buyer from a new build, claiming ‘heat pumps don’t work in NH’ (even though I own the HVAC company). The buyer withdrew, allowing the builder to sell the house for $75,000 more to someone else. Five years later, the heating system is still in great condition. The original buyer is still renting for $4,000 a month and asked me to testify against the ‘home inspector’ in court.

I totally agree! Our first home inspector caught the basics, but missed some crucial details that my carpenter BIL noticed right away.

I haven’t been too impressed with the home inspectors I’ve encountered. Some are good, but others miss important details like holes in basement joists for electrical cables.

Home inspectors require more than just a 2-day course and a trip to the store. It actually takes around 2 years to complete and get licensed in my area.

I’m not sure where you’re located, but that’s not the situation here. Massachusetts has stringent requirements for professional licensure. You need to complete a total of 75 hours of schooling, which can be done online in a week. After that, you can opt for ‘indirect supervision’ for 100 home inspections. Essentially, you pay someone to review your inspections and then you’re good to proceed.

In our previous home, the furnace struggled in temperatures below zero. Thankfully, the heat pump maintained the house at around 40 degrees.

This was a system I designed from scratch, including a Bosch IDS 2.0 WHOLE HOUSE Heat Pump. It’s built to handle temperatures as low as -14 degrees. The electric backup is there but rarely needed due to the correct sizing of the heat pump and great insulation. At 0 degrees, heat loss is 28,000 btuh and output is around 33,000 btuh. I can’t recall the exact output at 0 degrees, but it’s 36,000 at 5 degrees. These extreme temperatures are uncommon in that region. The system is fully modulating inside and out, with a 20 SEER AC and 10.5 HSPF COP averaging at 3 or more. Their electric bill is likely only a third of what it would be with propane.

Hey , there’s no furnace here.

I had a temporary insurance lapse because their inspector mistakenly thought we didn’t have a furnace or heating system since they considered our boiler to be just a water heater. 🙄 By the way, we’re in Minnesota.

Come on, that’s not true.

That’s not quite accurate buddy. I’ve witnessed you skilled individuals cutting through rafters and beams to set up your equipment. I suppose you believe the best defense is a good offense.

Honestly, I’m a bit lost with what you’re saying… but I’d lean towards you being the one on the defensive. Did your wife give you a hard time today?

Not quite there yet.

Hey Tony! Today, take a moment to center yourself and have some open, calm conversations with others. Remember, each day is like a blank page waiting for you to write your story.

Hey Tony, don’t forget those words.

“Home inspectors completed a 2-day course.”

Hey there, can you please gently rephrase for me?

Sure thing!

Appears to be licensed in NH, which is great news for you. You should definitely connect with the local Internachi chapter and network with them – it’s a fantastic way to generate more business opportunities! 🤝

Hey , do you remember that time you defended an entire industry’s licensing requirements and standards, even though they weren’t in place yet?

Did you know that half of the states in the US don’t have a professional license for home inspection?

Teaching opportunities are available in your state, especially for inspectors who need CE credits annually. By establishing strong relationships with inspectors, you can have a reliable source of referrals.

As a 25-year veteran in the field, I operate with one assistant and charge $2000 per day. I only work 4 days a week and my schedule is fully booked for the next 6 months. Surprisingly, I don’t actively promote my services and my trucks don’t have any signage.

It sounds like you’re not interested in expanding your business and prefer to handle everything on your own. It might be worth considering the long-term benefits, especially since you’re young.

Oaken Lochlan Oh man, I’ve got a ton of horror stories about inspectors. Ask any seasoned trades professional or real estate agent, they’ll have their fair share too. How about you? Ever had an experience with a master plumber or electrician? We all mess up sometimes, but it seems like everyone has a story like this or knows someone who does.

Hey there! You probably don’t know much about me or my spouse, and honestly, I’m not too worried about expanding my company. I prioritize spending time with my children at home every evening and morning. My family life is pretty well-rounded and we enjoy traveling together. It’s hard to find reliable people to work with though, especially in my state with an older population. Trade schools are scarce and the focus on college degrees in public education makes it tough. The student loan programs only add to the financial burden for this generation. Fun times! I was actually discouraged from pursuing trade school at 16 and told I’d end up as a bum by my so-called “guidance” counselor…

Congrats, you’re the winner!

So, let me ask you this: What exactly do you mean by securing the beam? Are you looking to support it with a post? Strengthen it by sistering it? Add more nails to the adjoining lumber?

Inspectors often use the term “CONSIDER” as a way to cover themselves. How long has the house been standing at this joint without any issues? Inspectors might want to think twice before causing unnecessary problems. You have knowledgeable tradesmen offering valuable advice that I won’t repeat. Listen to them and consider providing more pictures to get a complete view of the area. Best of luck.

Would not be allowed on a built up beam here, no joints unless supported by beam, the number of laminations doesn’t matter. It really depends on your local codes. That’s why so many people are debating whether it’s necessary or not.

It’s best to seek advice locally.

This doesn’t look great, I agree. Also, there seems to be an extra layer only in the top half. I’m thinking that some or all of these layers might not be structural. They could just be adjustments for a wider post bracket that the builder happened to have (whether it’s allowed by code or the vendor is a different matter). In any case, we need more information than what the OP has given so far. I will add that a two-member 2x laminated beam supporting joists doesn’t sound right, so it’s likely meant to be four 2x.

To ensure things are done properly, it’s advisable to consult with a structural engineer

Hey there, I’m a structural engineer. Just wanted to mention that while the advice on this page is helpful, it might not cover everything you need to know. It’s always a good idea to get someone with experience in beam bending and design loading to take a look. Even if you’re not seeing any immediate issues, factors like age deterioration and actual loading should be considered in residential construction.

Nailing patterns are great for shear walls and perpendicular loading, but beams need proper support to handle bending loads effectively. Adding more nails won’t necessarily make up for a loss in bending strength at the ends of beams. That’s why additional supports are crucial.

By the way, calling this a laminate structure is a bit misleading. LVLs are specifically engineered and tested elements, which is why their load tables are reliable. Simply gluing and nailing multiple layers of boards together doesn’t make it a true laminate structure.

I’m a structural engineer too, but I didn’t mention it before. David’s point here is really on point and he said it much better than I did haha. In groups like this, there are a bunch of “experts” who think they know everything, and just as many tradesmen who doubt engineers because we don’t physically build what we design. With these two groups alone, it can be tough to find trustworthy advice.

Sure, can you please provide the original text that needs to be rephrased?

So my point is that a structural engineer would be the best person to determine what is needed, not just an inspector.

Agreed. From a structural engineer.

I also construct houses and I understand the difference between true tradespeople and engineers who lack hands-on experience. Both have valuable information and experience, but assessing structural elements without seeing the full installation and other supports on-site is challenging.

I meant career tradespeople, not those who do construction as a hobby. I do a lot of DIY projects myself, but I don’t do it for extra money. I know not all tradespeople behave this way, but many tend to disrespect engineers. Based on my experience, it’s often because they lack knowledge in a specific area (as seen in some comments here). It can sometimes go the other way, but engineers usually don’t criticize tradespeople as much. Like you said, more information is necessary to answer the original post, but some self-proclaimed tradespeople here dismissed that and gave risky advice.

So … was there an issue identified in the inspection report that caused the inspector to make this comment?? It does say “consider” … that doesn’t provide much detail about a ‘problem’ in my opinion. is correct that IF it was typically built as a built up beam, then it is perfectly fine, so to speak.

The fact that the inspector used the term ‘consider’ without any other explanation/observation (at least that you provided) might not necessarily prompt immediate action. My reaction is similar … did/does the inspector have much knowledge about structures? Maybe he’s just uncertain. … mentions “securing”, also … what exactly does that mean? Not a very good choice of words in my opinion.

One thing to consider is whether the components were assembled properly/reasonably from the start. Without other signs of a problem (e.g. excessive floor bounce, wall cracks, floor tiles, etc) … there wouldn’t be a basis for labeling it ‘a problem’ …. in my view.

Before addressing ‘a problem’ … make sure you understand what the problem actually is.

What exactly is meant by securing the beam? What does the inspector recommend you do? If the inspector suggests adding a jack post here for support, it’s essential to have a footer below the concrete to transfer the load to the ground. It seems like the inspector might not have a full understanding of how everything works together. I recommend double-checking with the inspector to clarify the instructions before proceeding further.

It seems like there are indications on the floor that a post was previously installed or that there might be an issue upstairs; otherwise, adding a post might not be necessary.

Do you mind providing a clearer picture with dimensional data? Also, can you share the zip code of your location?

Did anyone mention the garage ceiling not being sealed to prevent CO/fire from getting into the home?

Hey Topher, I’ve read that there should be a layer of 5/8 for code sheetrock sealed with mud or the exposed Kraft face insulation is highly flammable.

If you’re experiencing movement issues with your floor, especially since it’s a garage, simply install a support post. Otherwise, you’d need to construct a wall to support the ceiling, remove the beam, and place four 2×10 lvl beams in various locations.

I believe the inspector is suggesting using lag bolts to secure the connection… I’d recommend getting ten carriage bolts and creating a zigzag pattern to tighten the two outer boards to the others.

It’s kind of hard to tell from the picture, but it seems like a ledger board holding the floor joist, right? If that’s the case, I would recommend leaving it as is.

How old is the house? Any issues so far? If it has been standing strong for decades without any problems, it’s probably fine. The standards of the past may not match today’s, but most houses withstand the test of time. ‘t try to fix something that isn’t broken.

There are many details missing here, respectfully. What specifically triggered this report? Is the floor sagging? What’s the size of the support area? What are the dimensions of the joists? More information would help in narrowing down the options.

Need more details to even take a guess on this one. Home inspection professionals can vary a lot. The majority (99%) just fill out a form and don’t really inspect thoroughly. My inspector missed the fact that my house had AL wire! Seems like your guy is in the 1%. What exactly is bothering him? Is it the lumber that’s pieced together? How old is the house? What’s the length of the beam? Are the boards all the same size and bolted through? Any signs of a removed post on the floor? If it’s the seams on the lumber and there are no fasteners, you can bolt it through. I’d recommend using threaded rod with large washers and nuts on each side. Drill, insert the rod, bolt it tight, and cut the excess. Even better would be to get two steel plates made and bolt them on each side of the beam. Mark, drill, insert the rod, and repeat for the other side. It’s tricky to get the holes straight. Consider consulting an architect or engineer. Drilling holes might cause more damage than good. If the beam has been there for over 20 years, it’s probably stable. One more thing, you mentioned it’s the garage. Aside from the beam, there should be firestop sheetrock above. It’s a big fire hazard. I’ve never heard of unprotected wood joists above a garage below a living space. Same goes for partition walls. Also, the insulation seems to be installed backwards. The vapor barrier should face the heated space. Exceptions may apply for very humid climates, but I don’t have experience with that.

I don’t see any problem here. Those 2x’s seem to be connected securely, forming a beam.

Why isn’t there fire-rated drywall on the ceiling?

Building code requires fire-rated drywall on any walls or ceilings that are shared with living spaces.

When it comes to needing support, like a support wall or a beam, this public forum isn’t the best place for advice. You really should consult with a structural engineer who can come out in person to assess the situation. Only then will you receive accurate and helpful guidance.

I may not be a structural engineer, but I did spend the night at a Holiday Inn recently…

No problem. Just purchase a floor jack and use it to lift it up.

If you don’t end up needing it, no harm done for playing it safe. But if you do, you’ll be thankful it was there.

Just make sure to stagger the beams and butt joints. If you have two butt joints side by side, it could cause a sag in that spot.

Do you think the breaks in 3 out of the 5 timbers, especially in the same spot as highlighted by the red box, mean that this might not actually be a true laminated beam?

Make sure to check if all 4 are necessary for the beam. Maybe only the center two are needed and the others were added for a different purpose.

My home inspector pointed out several supposed structural issues in the attic, but multiple framers have reassured me that everything was done correctly.

I’ve come across both top-notch and terrible home inspectors before. Personally, I wouldn’t fully trust one to handle this situation. I’d recommend getting someone with more expertise, like an engineer, to take a look. Do you think there’s an issue up there? And how long has it been like this?

Hey there! I wanted to express my gratitude for the advice. I plan to go through these comments soon. Right now, it appears that adding more pictures/information would be beneficial.

It appears there are distinct issues here. A squeaky subfloor can be caused by the lack of glue, use of smooth shank nails, non tongue and groove plywood, and possibly 5/8″ thickness instead of the standard 3/4″. However, homes were built for years using 1/2″ non tongue and groove plywood without ring shank nails and no glue. If this is the case, it’s unlikely to be a structural problem.

On the other hand… I have some concerns about the sloping floor, how the stack is framed, and the fact that it appears to be moving. While I may scoff at an inspector pointing out a problem that may not exist, if that beam is indeed moving, it could indicate a serious problem. Have you already bought the house? Or are you still negotiating? If you’re still in the negotiation phase, I would recommend working with your real estate agent to get the seller to cover the cost of a structural engineer to assess the framing and vertical columns. They can provide a brief report with potential solutions, if needed. Just make sure they are a professional engineer (PE). It’s not a major issue and you can likely find someone local without spending a fortune. Be cautious and rely on your realtor to avoid risking the sale by being too aggressive in this market.

Just to be clear, if that beam is moving, my money wouldn’t be on the stack with cantilevered ends at the 4′ red marks. The issue may lie with the Lolly columns being directly on a 3″ concrete floor or on questionable clay fill. This could cause major problems down the line. Adding more vertical columns might not solve the problem. It’s important to jack up the beam, replace all supports, and figure out what’s causing the issue. If worst comes to worst, you may need to replace all columns and the stack with something more heavy-duty. It’s a pricey fix, but a necessary one to avoid further damage.

Hey @tony, thanks for sharing that info! We’ve been living in this place for roughly 3 years.

It’s really not typical to see sloping floors in a 20-year-old home that was well built. A little settling is normal, but this seems like it might be more than that. Feel free to reach out if you need advice or have questions – just send me a DM. I’m more than happy to help! Buying a home can be super stressful, especially if you’re not a contractor and don’t know what steps to take.

Thanks a lot!

Got it. Just so you know, this is not an emergency. Since you’ve been living there for a while, the main question is whether it has shifted over time. It’s pretty common for settling to occur, and sometimes a house settles and then stays put. I experienced that with our first home. You can use a level on the floor to check if it’s really off balance. (If I seemed overly concerned in my previous comment, it’s because I thought you were in the process of buying… I didn’t want to downplay a potential future repair…

Hey, can you check how the garage floor looks? Specifically where those columns hit the floor? Ideally, they should pass through the garage floor, which would indicate a proper poured footing and that they were installed before the floor was poured

It’s important to stay hydrated throughout the day.

The taste of fresh strawberries is delightful.

No content

I prefer to be alone most of the time.

No content

Check with the city permits department to find out what work has been done on the house. It’s important to know if the changes were approved by the city building inspector.

Sure, duct tape.

Have you ever used gorilla glue?

If this is a garage, where is the fire separation? I call BS. And what does the Home Inspector know?

You can make plates out of a piece of flat iron or you can get a 10-inch or wider lag bolt with a 5/16 x 3-inch x 8 staggered pattern, that should work fine.

Consider hiring an engineer first. There might be no need for action here. The inspector is flagging a splice point in a multi-ply beam, where the strength (moment and shear capacity) is significantly reduced. Splices are typically placed over supports like columns, walls, or other beams. It’s possible that everything is fine, or the two remaining plies could be under excessive stress.

💯💯 I’m no engineer, but you can’t make a call based on just one photo like this

I have a question about fire safety in relation to the ceiling. Is 5/8 Sheetrock required by the fire code?

If that beam was assembled on site, the joints shouldn’t be in the same spots. It’s probably necessary to have additional support under a set of joints like those.

If you’re using the space above the garage, shouldn’t the ceiling be covered with 5/8 inch drywall to meet fire safety regulations?

The span seems a bit short. Is the floor above bouncy? Two 2x’s might suffice, with the rest serving as pack-outs to align with the floor joists. It would have been better to offset the seams for added strength, but it may not be necessary.

A friend of mine was selling his house, and the sales agreement specified that the deposit wouldn’t be refunded unless the pre-sale inspection uncovered issues not mentioned in the agreement. The buyer’s inspector was quite incompetent, as he wrongly flagged the septic system due to a faulty leach field and alleged water damage in a particular area he examined. When I was requested to inspect the property, I discovered that the inspector had missed inspecting the new leach field, focusing on the old ones instead. I highlighted this in my report, providing evidence of the new system’s approval by the health department and debunked the water damage claim with photographic proof. The case went to court, and after presenting all my evidence, the judge turned to their “expert” for an explanation. The expert couldn’t defend his claims, leading the judge to rule in our favor without hesitation.

If you’re dealing with your garage, it’s essential to ensure it’s both airtight and structurally stable. When it comes to structural aspects, seeking advice from a structural engineer is crucial, regardless of how hands-on you may be or even if you’re a mechanical engineer like myself!

Is the beam running perpendicular to the garage doors & is the beam centered between the doors. If it’s centered between the garage doors, I’d suggest installing a 5-inch steel lally column with a steel plate to provide support for the full width of the beam. The lally column would require a 4-5 foot footing.