Stucco Cracks at Door and Window Corners | which ones are serious

Stucco cracks at window and door corners, whether diagonal, horizontal or vertical, may allow moisture into a wall and possibly be an indication that there are structural issues. Structural engineers usually examine these cracks as part of their overall evaluation of a home. Much of the time these cracks are not major, but more of a maintenance issue involving sealing, patching, or caulking. Which if not done, over time may cause extensive damage to a wall and possibly mold problems.

Homeowners should know to identify which cracks are serious or a structural issue.

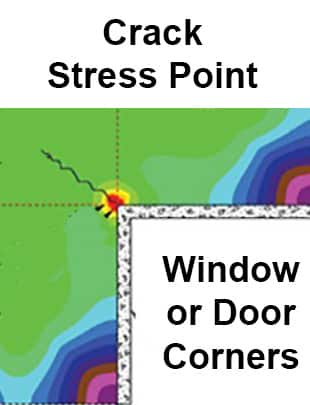

Stress – One of the main reasons for cracks

One of the most common causes of cracks at window and door corners is stress. When a home is first stuccoed during the construction process the stucco goes through a curing process as the stucco hardens. This occurs basically 3 times in a Traditional hard coat application. It occurs in the application of the:

- Scratch coat

- Brown coat

- Finish coat

If one or more of these three coats does not cure properly, then the stucco will be a little weaker and there will be more shrinkage cracking. There will be both microscopic and hairline cracks. However, the cracking is generally not evenly dispersed over the entire wall and there is a tendency for more stress to be concentrated at the corner areas of doors and windows. Thus, there is more of a tendency to crack at the corner areas due to the stress.

Re-entrant cracks

These corner cracks are often referred to as re-entrant cracks. This same process is not unusual in concrete as well. Both concrete and stucco have several things in common: Portland cement, water and sand, so it not inconceivable that they both suffer from shrinkage cracking. The good news is that the majority of the time, shrinkage cracks do not leak. They are a natural process and normally a maintenance issue at most.

The size of the window, door or other opening in a stucco wall

If a window is a small 12 inch by 12 inch window, all other things being equal, it will not experience as much shrinkage cracking as one that is 6 feet by 4 feet in size. Likewise, a door 3 foot wide will not have as much or as server cracking, as a glass sliding door ten foot woot wide. The larger a door or window opening, the higher the likely hood that there will be a higher level of stress.

Window cracks running to other wall penetrations

It is not uncommon for a crack from a window corner to run to another penetration nearby. It might be to another window, door, vent, or to a pipe going through the wall. Basically, the crack is a form of stress relief for the stucco.

It may be occurring for many reasons, including lathing issues, workmanship or that the stucco may lack sufficient cement in it. Thus, the stucco is weak and will crack easily. If there are a lot of these types of cracks going to other penetrations, it may be wise to consult with a professional stucco contractor or engineer and possibly have the stucco tested for strength, if they do not have a satisfactory explanation for the cause.

Note. Not all cracking is due to shrinkage and not all cracks in window and door areas are at the corners. Shrinkage cracks are considered an internal cause of cracking. There is also, other internal causes and there are cracks that are caused by external issues.

No control joints or improperly installed or placed

To allow for some movement of a stucco wall, including movement due to expansion and contraction, as well as stress, stucco contractors will often place control joints in a wall. You could say that they divide the wall into sections. The purpose of the control joints is to allow for limited movement with minor or no cracking. Having properly installed control joints will also help reduce cracking at window and door corners.

There are various types of these joints, and a variety of companies manufacture them. The type and the location of the control joints are often specified by an engineer, the architect or by the manufacture or designer, if a proprietary or an EFIS system is used.

There are sever types of joints; most are either a one-piece joint (“M” shape or “V” shape). Another type of a one-piece joint that is often used at doors and windows is a “J” control joint. A third type of control joint is a “two-piece” joint the often has a membrane behind it to prevent moisture from passing through the joint. This type of joint may allow more expansion and contraction than the one-piece joints, i.e. ¼ to ½ of an inch.

Controls joints are generally required by the Building Code for Traditional hard coat stucco applications.

Building Code

The majority of Building Jurisdictions have the following basic requirements for Traditional hard coat applications.

- Joint spacing should not be greater than 18 feet in any direction.

- No panel area should be greater than 144 sq. ft. on vertical applications.

- No panel should exceed 100 sq. ft. over horizontal, curved or angular sections.

- The length-to-width ratio should not exceed 2 ½ to 1 in any given panel or section.

“J” control joints are often used around window and door frames and are manufactured with expanded flanges so that a crack is less likely to occur or be exposed. The design of “J” joints locks the stucco to the edge of the joints and reduces separation at the joint’s edge.

Note, that control joints are not always located in the middle of a window as shown in the photo. The photo is just one example.

Tensile strength of stucco

Stucco and concrete have a number of similarities. They both have cement, sand, and water as part of their mix. They both have excellent compressive strength: ie most concrete may have a compressive strength of 2,500 psi to 4,000 psi and stucco often has a compressive strength of 2,000 psi to 3,000 psi.

However, traditional concrete may have a tensile strength of 300 to 700 psi. but stucco may have only a 100 to 200 psi tensile strength, much less than concrete. If you add rebar to concrete, then tensile strength goes up exponentially.

Basically, due to the weak tensile strength of stucco when compared to some materials, it may be more prone to cracking when there is movement of a wall, foundation or if there is expansion and contraction due to significant thermal changes.

Dissimilar materials against each other may cause cracking

One of the common areas to find cracks in stucco is where there is a transition from stucco to another type of material or cladding. Many homes will have two, sometimes three or more types of claddings for architectural purposes. Perhaps a mix of stucco, stone, vinyl, wood, or some other type of cladding. At these transition points it is not uncommon to observe stucco cracking. Mostly due to dissimilar materials having different expansion and contraction coefficients, or lack of proper flashing. The same concept applies to windows and doors and the stucco around them.

Check around the perimeter of your window and doors for cracks and gaps

Window and door frames are not stucco, they are usually wood, metal, vinyl or a PVC type of material. Thus, the frame materials expand and contract differently and react differently to rain and temperature changes than stucco. This creates stress and gaps that may result in cracks, leaks, or both.

Look carefully. Check to see if the stucco goes right up against the wood, metal or vinyl frame of the window or door or if there is a gap of approximately 1/8 to ¼ of an inch, plus or minus a little. If there is a small gap, and it appears sealed or caulked, that is usually a good sign and most likely there is probably a piece of baker rod behind the sealant or caulking. This will help prevent moisture intrusion and reduce or prevent cracks; for it allows for limited movement without cracking the stucco. If there is none, it is often considered an issue by forensic inspectors. Contractors can save a little time and a few dollars by not taking this extra step, but in the long haul, it may turn out to be a costly problem for the homeowner. Note, that the building code may not require this configuration of materials, but the building code is just a minimum set of requirements, not necessarily the best way of doing something.

Manufactured foam trim or moulding around windows and doors – they may have very thin cracks

Architects and home builders will often install pieces of foam trim or moulding around windows and doors to accent the doors or windows. The foam trim looks just like the rest of the stucco on the building but may be a different color or texture to highlight the windows or doors. This trim is usually secured in place by a construction grade exterior adhesive. If the trim is not installed properly, thin hairline cracks may appear where pieces are fitted together or secured to the stucco. These cracks are usually a maintenance item and occasionally may allow moisture intrusion. Should any cracks exceed 3/16 or 1/8 of an inch, then it is more of a concern and further investigation as to the cause is suggested.

Leaks at windows are not always due to stucco problems

Leaks around windows are not always due to defective stucco, poor application or cracking of the stucco, but due to issues with the windows or frames themselves. Window frames will occasional get damaged when being transported to the job site by shippers who are not always gentle in handling the windows or the packaging that the windows were wrapped in during transportation may have been improper or insufficient. Additional, windows are usually not thoroughly inspected before being installed and even if they are damage, some workers will still go-a-head and install the window.

Installed improperly. Inspectors will tell you that from time to time, they will find a window, or even a group of windows installed upside down because the laborer did understand how to properly install the window. When this happens, most windows will leak because the drainage design of the window will fail.

Another problem is that the material used to seal sliding and other types of windows and some doors may be worn out or damaged. These materials are intended to keep water, insects, or wind from seeping or blowing through. They are often tubular gaskets, foam tape, fuzzy types of materials, etc. Check these as well.

Homeowners should also check a leaking window to see if the frame or any of the joints are damaged or pulled apart at a corner or in some other area of the window. Also, look for cracked welds in both metal and vinyl windows, and if you find any, the manufactures warranty may cover the problem.

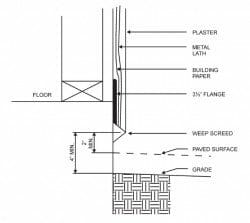

Windows that were not properly flashed

If certain types of building paper or wraps were used and they were exposed too long to UV rays or a destructive environment, then the materials will often degrade over time. Should a house sit for extended periods of time with these types of flashing materials exposed, then they may fail.

At times the flashing, regardless of the type will become damaged in the construction process itself, and occasionally the window may never get flashed. Failure to properly install and flash a window is one of the main reasons for window leaks.

Warning signs that a window may have a leak

Efflorescence, bubbling, peeling, flaking, blisters and mold

Water leakage is a common issue with stucco in areas where seasonal rain is the norm. If water gets behind stucco it will soften the areas that it comes in contact with, eventually causing the stucco to flake, peel, bubble or break away and fall off, at times in sheets.

Efflorescence.

When there is moisture in a stucco wall, at times it will saturate the stucco from the back side due to a leak in the window area. Since stucco is a porous material, it may migrate to the exterior side through a capillary type of process and then the sun and wind on the wall will cause the moisture to evaporate, leaving a white salt crystal substance on the walls’ exterior wall called efflorescence.

Finish coat of stucco flaking off

If the top layer or finish coat of a stucco wall is peeling off or flaking, it may be due to moisture behind it which causes it to separate from the rest of the wall. Basically, it loses its bonding power.

Bubbles under the stucco finish coat or paint

If there are bubbles under the top layer of the stucco or paint, it may be caused by water being trapped in small pockets or voids. At times if you push on these bubbles or blisters, they will rupture, and water may even drain out.

Damp looking stucco

Should a section of stucco located close to a window or in the vicinity under a window be slower to dry out than the rest of the stucco on the home, then there is a chance that it’s because the window or cracks around the window has allowed moisture to enter into the wall behind the stucco.

Mold on the stucco near or under a window

If there is a dark like discoloration on the stucco, it may be from mold or some other source. At times, it develops from moisture getting into the stucco from the exterior side and at other times, from moisture on the backside of the stucco.

Depending on the amount and severity of the above issues; maintenance, repair and sealing of cracks around the windows or doors is often necessary. Should the cause be due to other issues, then repair of them is wise as well, for moisture in a wall can cause wood rot, structural damage, as well as mold.

Structural concerns involving cracks at window and door corners

Evaluating if cracks at window and door areas relate to structural issues is a two step process.

Step 1. First examine the cracks at any door and window areas or corners.

Step 2. Examine the rest of the house for “Red or Yellow” flags that there is or may be a structural problem with the house as whole, just not at the windows or doors.

Determining the seriousness depends on various factors: including

- The number of cracks around doors and windows

- Location of the cracks; at corners or parallel with the frame, or perpendicular to the frame

- Size of the cracks. 1/8 inch or larger

- The cause of the cracks

Structural engineers

They will not only look at the cracks at the doors and windows, but they will also examine the entire house. Not only will they approach their examination from a site-specific viewpoint, but they will also take a global view to the overall problem: meaning that they will look at the entire neighborhood and surrounding area as part of their investigation.

Rather than being just site specific they will determine if there are broad geotechnical issues or problems in the area. They will evaluate the types of soils in the area and if there has been any soil movement or landslide concerns. They may check local geological maps and do a visual check to see if nearby streets, curbs and gutters are wavey or slightly offset, indicating the soil is shifting or moving. They may even research if there are any underground tunnels, subways or old mines that may cause subsidence or other issues.

On site they will examine the types of soils the home sits upon and if there are expansive soils or evidence of slope creep or settlement. All of these types of things can cause the foundation to shift or crack, which then may cause the stucco to crack, including around the doors and windows.

Factors indicating a crack may be more serious or structurally related

1/8 inch or wider. Cracks over 1/8 inch wide or wider are often an indication that there may be a structural issue involved.

Over 3 ft long. There is no specific length that contractors or engineers feel is an indication of structural problems, but some feel that one’s over 3 feet in length may deserve more consideration.

Cracks that extend to the corner of the building. Cracks that run from a window to the corner of a building may be given extra weight in analyzing the cracks. At times there may be a crack in the foundation near the corner; perhaps the foundation corner has dropped or settled.

Cracks running though the foundation and extending to window or door corners. Should a crack run from a window or door corner and continue through the foundation or basement wall, then it would fall into a significant structural concern category. These types of cracks should be reviewed by a structural engineer.

Structural issues dealing with soil and foundation problems often cause cracks in stucco

Stucco is not a flexible type of cladding for a home. It is rigid and considered to be more brittle in nature than a wood or vinyl cladding. Thus, more susceptible to cracking when it experiences stress forces from soil or foundation movement. Soil movement alone can cause concrete foundations to crack and or fail. Once the foundation shifts or moves, then the framing that is attached to it will likewise move.

All of these forces can easily result in cracks at door and window corners. Likewise, if wood framing members get exposed to moisture form stucco leaks or other sources. They may deteriorate or lose structural strength from wood rot and once this happens the framing supporting the stucco may move or fail.

Homeowners should not rule out that structural issues are causing the cracks and therefore, should look for other warning signs around the home of structural problems.

Other warning signs that a home may have structural issues include:

- Cracks in the drywall

- Doors or windows not opening or closing properly

- Sloping or sagging floors

- Roof wavy, sagging or bowed

Learn other warning signs of structural issues.

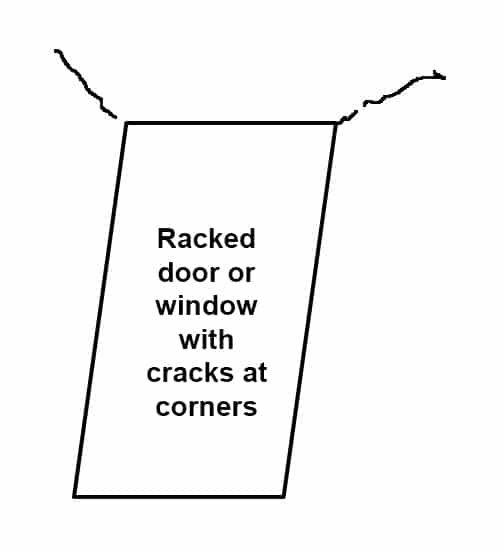

Racking – a serious warning sign

If doors and windows are racked and there are cracks at the corners or sides, then there is a serious structural concern.

Racking is when the sides of the doors or windows are not at a 90-degree right angle to the top and bottom. For racking to occur, there general has been tremendous forces that caused it. Examples would be a tornado, hurricane, earthquake, landslide, or significant slope creep. If severe enough homes may even collapse.

If racking has occurred, there may well be cracks and gaps at the edges of windows and doors that will allow water to seep into.

- Conduct a yearly inspection of all exterior doors and windows, as well as, all of the stucco cladding on the home.

- Check the interior window and door areas for evidence of moisture, stains or mold.

- Seal or repair all cracks at window and door corners.

- If there are foam trim pieces around doors or windows, look for cracks there as well.

- Examine where any stucco abuts window and door frames for gaps or cracks. Seal as necessary.

- Look at the actual window frame itself, whether metal, vinyl or wood for damage or cracks.

- Be sure that all weep holes in window and door frames are clear of debris and that they are not clogged.

- If there are significant or concerning cracks, racking, or there is an indication of structural problems, then consulting with a qualified stucco professional or structural engineer is wise.

- If the cracks appear to be a maintenance type thing, then repair or caulk as needed. Many contractors will use an exterior silicone caulking because it is very flexible, even after it has cured, so it makes a good sealant in many types of applications.

Bottom Line

Stucco cracks at window and door areas and corners are very common and generally are not a structural concern. However, if moisture is penetrating through the cracks, there is a risk of structural damage, wood rot and mold.